What is the Most Advanced Fire Protection Technology for Electric Vehicle Lithium-ion Battery Packs?

Power Battery Fires have Become a Serious Concern for Electric Vehicle Manufacturers and Consumers alike

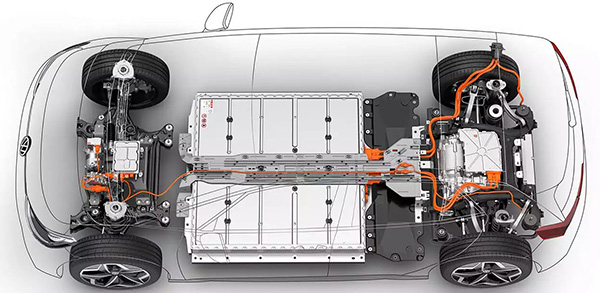

As electric vehicles (EVs) have become more popular, the lithium-ion battery packs that power them have become the subject of safety concerns. The problem with fires caused by battery packs has already been seen in electric cars. In April 2019, an electric car caught fire while it was charging at a garage in Shanghai, China. The owner had left his car unattended while it was charging, and when he returned to his garage later that evening he smelled smoke and found his car engulfed in flames. The fire department quickly responded to put out the fire, but not before causing significant damage to the garage and its contents. It's important to note that this type of incident isn't unique to electric cars — any electric vehicle with a high-voltage electrical system can experience problems if something goes wrong with its charging system or its battery pack.In order to address this issue, many manufacturers came up with safety precautions like thermal management systems and fire protection systems.

A Combination of Thermal Management and Active Thermal Runaway Control is Regarded as the Most Effective Fire Protection Technology

Battery Management System (BMS)

In today’s world, thermal management has become increasingly crucial in ensuring safety at all levels — from homes to businesses and industrial facilities.

◆Battery cells: Many individual battery cells are connected together to form a battery pack;

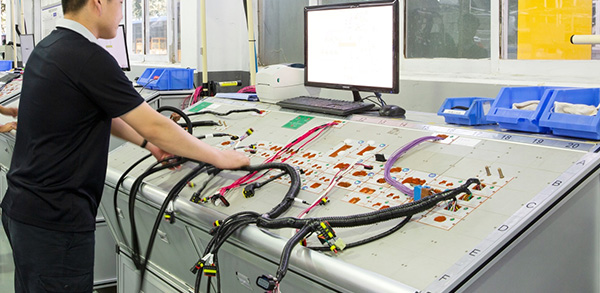

◆Battery management chip: responsible for sensing battery status and sending control signals;

◆Voltage, current, and temperature sensors: measure important parameters such as battery voltage, current, and temperature;

◆Controller: manage battery charging and discharging, as well as temperature adjustment and other functions;

◆Communication module: Provides data transmission services for vehicle upper-level systems.

--Why BMS?

Batteries have internal resistance that limits their ability to accept current. When more current is drawn from a battery than it can handle, heat is generated inside the battery as it struggles to cope with the extra load. This results in higher temperatures within the cells and eventually leads to failure if not prevented or managed properly. Heat also affects battery life because it shortens cycle life by causing more stress on every charge/discharge cycle. In addition, excessive heat can lead to thermal runaway which could cause fire or explosion.

The thermal management system in electric vehicles monitors the temperature of li-ion cell and communicates with an active nitrogen fire protection system to prevent battery fires and control battery thermal runaway. For example, Nissan developed a thermal management system that helps reduce heat generation inside its batteries during charging or discharging processes by controlling the temperature inside them. This reduces the risk of overheating and allows for faster charging times without compromising on safety features.

Active Nitrogen Fire Protection System

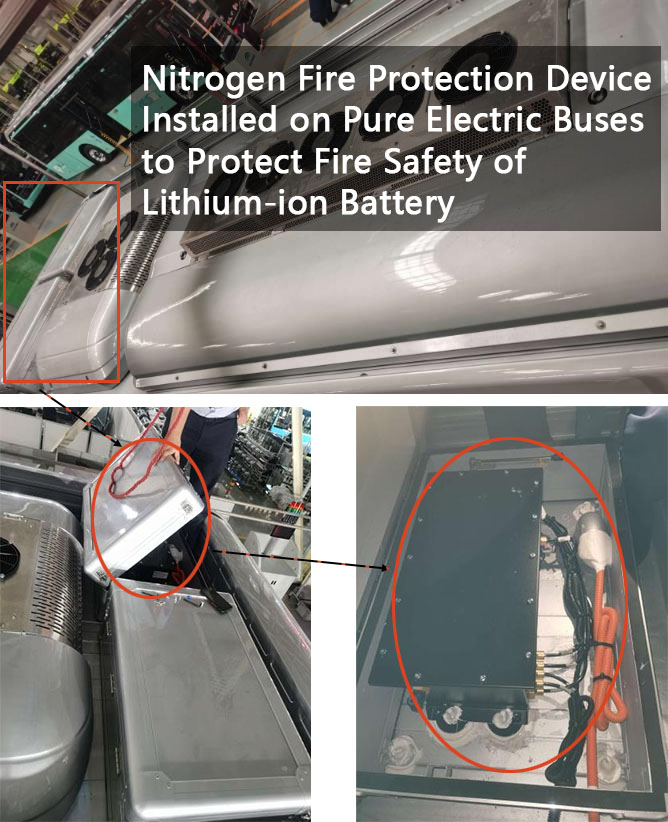

The fire accidents of pure electric vehicles are more frequent and severe than those of gasoline vehicles. In the past two years, there have been many battery fires in pure electric buses. The reason is that in the development process of pure electric vehicles, the safety design of batteries has not been fully considered, which has caused many serious accidents.The internal short circuit or thermal runaway fire of the battery cells leads to the complete vehicle fire. At present, the first-line thermal management system can only monitor temperature at key locations. Therefore, the prevention and control measures should be strengthened in terms of both technical level and operational level to improve its ability to fight fire and ensure lithium-ion battery safety.

--Nitrogen safety protection system for the entire life cycle of lithium batteries

As we all know, a large proportion of fire accidents in pure electric vehicles are caused by internal short circuits or thermal runaway fires in battery cells, which lead to the entire vehicle catching fire. So, how can we completely prevent the battery from catching fire in extreme circumstances?

There are three main factors that cause battery combustion: "combustibles", "oxygen" and "ignition source". Under the premise that the "ignition source" (internal short circuit) is determined, if the "combustibles" and "oxygen" can be completely cut off, the problem will be solved.

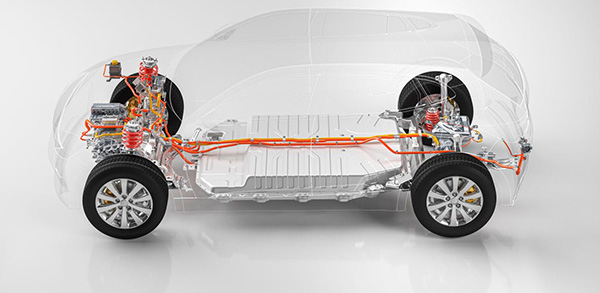

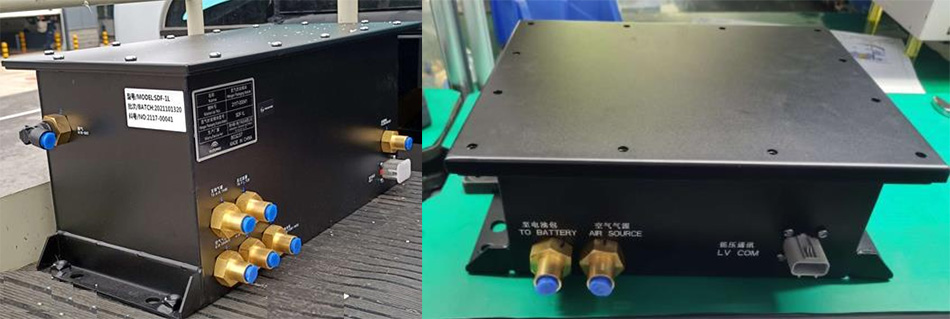

Based on the characteristics of lithium batteries that are less likely to produce oxygen after thermal runaway, Guchen Electronic took the lead in developing a long-lasting oxygen isolation and highly reliable nitrogen protection system. The nitrogen gas is used to eliminate oxygen in the battery box in real time, blocking the combustion path of the lithium battery and completely eliminating the combustion conditions in the battery box. Even if an internal short circuit or thermal runaway occurs in the battery, because there is a nitrogen protection system around it, just like a match cannot ignite in an environment without oxygen, the high-purity nitrogen environment will nip the expansion of thermal runaway in the lithium battery in the bud, which is equivalent to Nitrogen builds an invisible and intangible protective shield for the battery.

Guchen Electronic cleverly utilizes the compressed air prepared by the vehicle's air compressor and separates the vehicle's compressed air into high-purity nitrogen through aviation-grade nitrogen separation technology;

In order to ensure that the air pressure can be adjusted throughout the entire process, the Guchen Electronic development team designed a multi-stage pressure reduction and current limiting structure. In normal working mode, the compressed air loss of the entire vehicle does not increase by more than 1%. In addition to improving safety, the nitrogen system developed by Guchen Electronic also has many practical functions in terms of reliability: for example, during floods, many new energy vehicle battery packs have experienced varying degrees of water intrusion. In addition to the insufficient protection level of the battery pack itself, the seal failure of some battery packs is also the key reason for water intrusion. Existing battery pack air tightness inspections usually require after-sales service personnel to regularly bring professional equipment to the site for maintenance inspections. The real-time battery air tightness detection function of Guchen Electronic nitrogen protection technology effectively solves this problem. Through the online diagnosis technology of the big data platform, the pressure change status in the battery pack can be detected and judged in real time, realizing automatic detection, diagnosis and early warning of battery pack sealing abnormalities, and reducing the risk of battery water intrusion. At the same time, the high-precision detection device in the battery pack enclosure is used to effectively identify the early thermal runaway characteristics of the battery pack and achieve accurate real-time warning and control; Using the multi-stage filtration and automatic drainage functions of the nitrogen protection system, the battery pack can be controlled in a low-humidity environment in real time, eliminating safety risks caused by condensation in the electrical box in hot and humid areas.

The application of active nitrogen fire protection systems has become a leading technology in the area of thermal runaway control. The reason for this is that these systems are able to use active nitrogen injection to prevent thermal runaway and its propagation in lithium ion battery.. Additionally, they can be used as part of an integrated approach with other passive and active safety systems. For example, they may be used in combination with thermal management system to monitor the battery cells temperature and eliminate fire hazards of battery cells.

At present, due to the improvement of structural design and safety technology, most of the Yutong electric buses have been equipped with the active nitrogen fire protection system. From great simplicity to simplicity, you can achieve multiple things with one stone. Guchen Electronic's newly developed nitrogen protection system solves the safety problems of pure electric buses by blocking combustion conditions in the battery box, and will bring more new enlightenment to the development of industry safety technology.

Message

If you are interested in our products, please fill in the message form below. Our sales representative will contact you within 24 hours.