11 Most Important High Voltage Components of Electric Vehicle

Electric vehicles (EV) are gaining popularity, but people often wonder about the high voltage components of an electric vehicle. These components are critical to make a functional EV. Here are 11 of the most important high voltage components that are used in electrical vehicles:

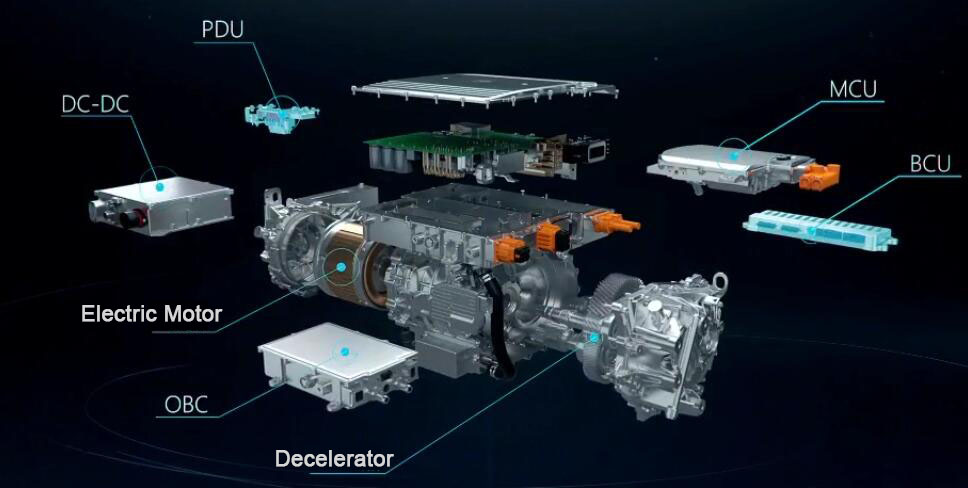

1. Traction Battery Pack

2. Electric Motor

3. Motor Control Unit (MCU)

4. Power Distribution Unit (PDU)

5. PTC Heater

6. Electric AC Compressor

7. On Board Charger (OBC)

8. DC-DC Converter

9. Manual Service Disconnect (MSD)

10. High Voltage Wiring Harness

11. Charging Port

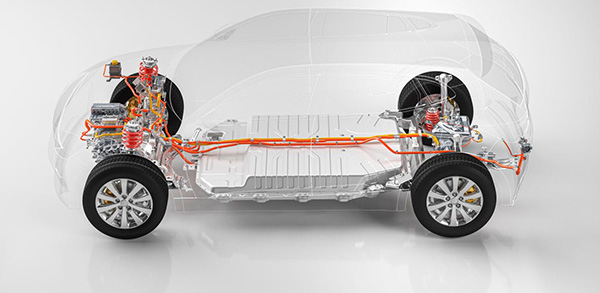

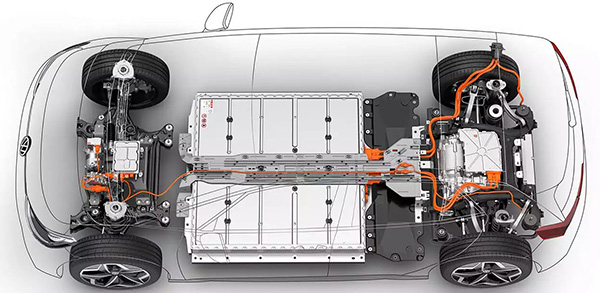

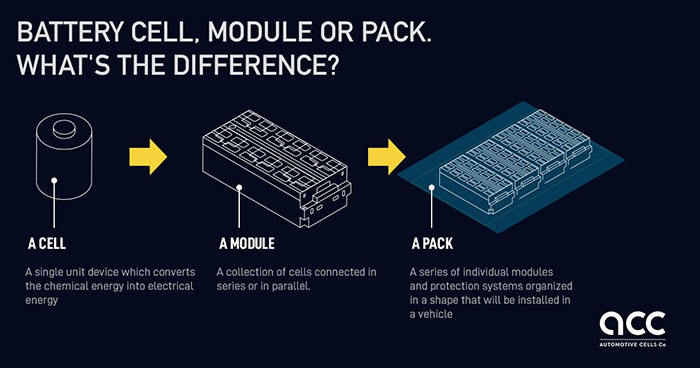

1. Battery

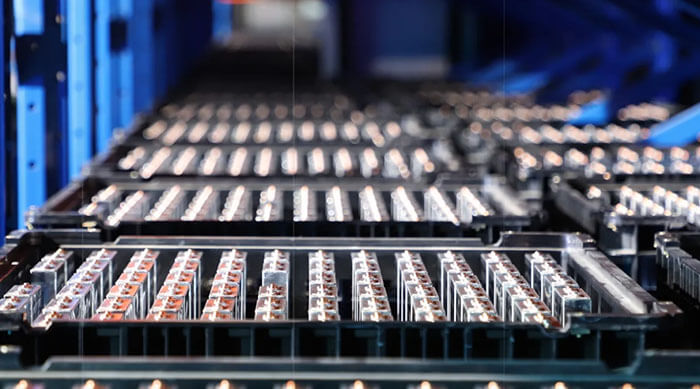

The traction battery pack is where all the magic happens. It is one of the most important components of an EV because it stores all of the energy generated by a battery charger or power plant. The battery pack is made up of many cells/modules, battery management system (BMS) to ensure battery operate safely, and thermal management system (BTMS) to power electronics for optimal operation. Together they create a unit that stores energy for powering your EV.

Image source: acc-emotion.com

Most batteries use lithium-ion technology which allows for a lot of power to be stored in a relatively small space. It also has a high energy density, which means that it can store more energy per unit weight than other types of batteries.2. Electric Motor

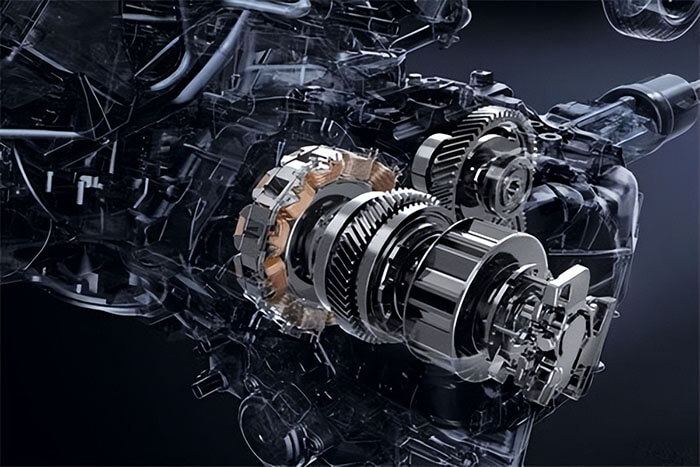

The electric motor is crucial for the operation of electric vehicle. It generates the power that makes an EV go, and it is responsible for converting electrical energy into mechanical energy.

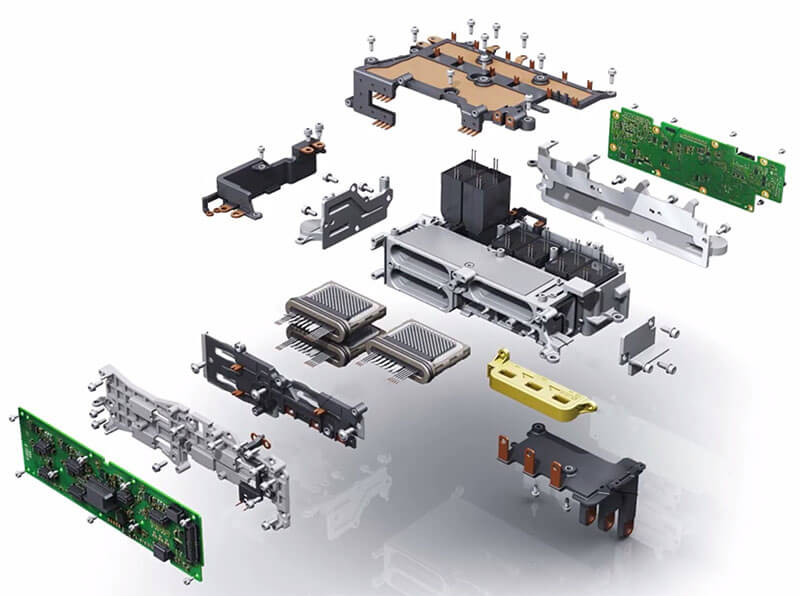

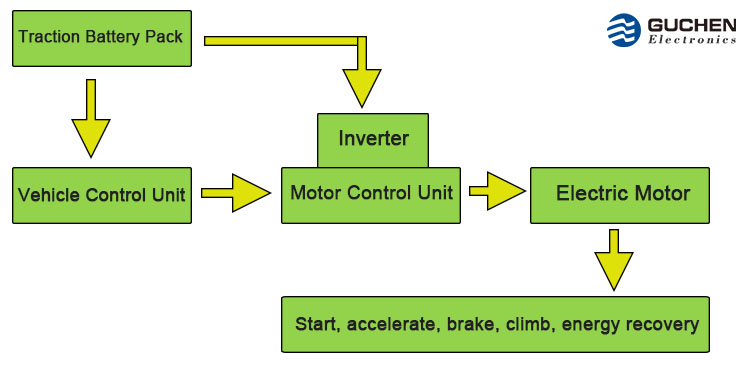

3. Motor Control Unit (MCU)

MCU is an electronic device that controls the operation of an electric motor.◆ This controls how much electricity flows through an electric motor so that it can operate efficiently without overheating or damaging itself due to excessive strain on its circuits or wires; this includes making sure that there's enough torque available when needed.

◆ The MCU controls the speed and torque of an electric motor by regulating current flow through the coils that make up each electromagnet in the motor's stator (the stationary portion of an electric motor).

◆ The MCU also monitors various conditions such as battery voltage and temperature as well as vehicle speed and throttle position sensors to ensure that all components are operating within their design limits and to keep them running smoothly together as one integrated unit.

(1) Drive control: The inverter inside the MCU inverts the two-phase DC power provided by the power battery into a three-phase AC power with adjustable voltage and frequency, which is supplied to the motor and drives the vehicle to run.

(2) Speed control: By using PWM control to change the voltage and frequency of the three-phase alternating current output by the inverter, the speed and torque of the motor can be changed, thereby regulating the EV speed.

(3) Direction control: By changing the conduction sequence of the IGBT in the inverter, the phase sequence of the output three-phase alternating current can be changed, and the motor can be reversed, thereby changing the running direction of the vehicle

(4) Braking control: The electric motor operates as a generator to convert kinetic energy into electrical energy to generate three-phase alternating current, which is converted into direct current by the inverter and fed back to the power battery for regenerative braking.

4. Power Distribution Unit (PDU)

The PDU is an assembly of various components that provide power to various parts of an electric vehicle (EV). It distributes power from the battery pack to the electric motor and other components, such as climate control system. It is typically a large box with many wires and high voltage connectors that must be able to handle high voltage DC power.5. PTC Heater

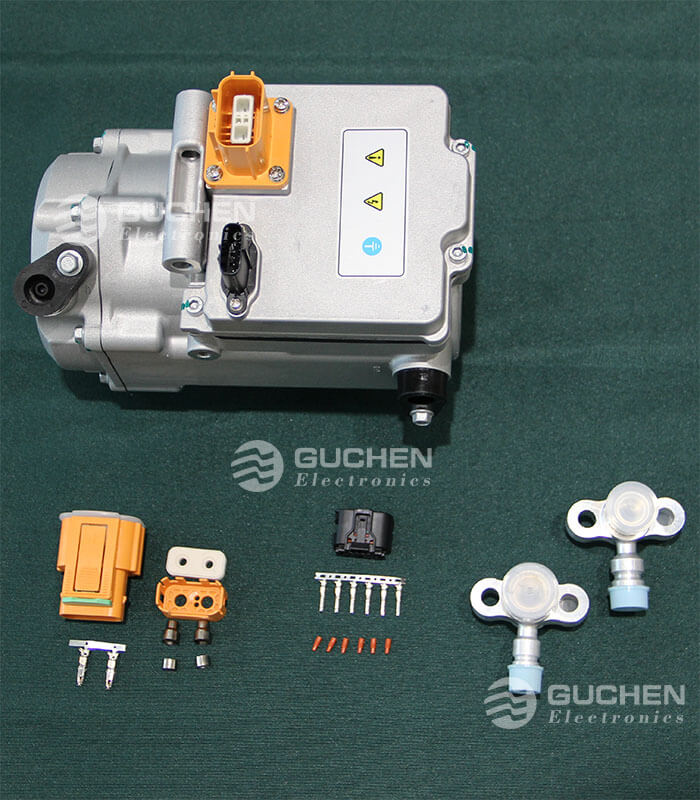

The PTC heater is an electric heating element that uses a positive temperature coefficient (PTC) ceramic resistor to generate heat. When voltage is applied, it generates heat with resistance change, which can be used to produce heat for various applications such as car cabin heating and battery pack heating.6. Electric A/C Compressor

The electric AC compressor is powered by the electric motor, and works together with other parts such as condenser and evaporator to provide a comfortable environment for passengers.The electric AC compressor has three main functions:

◆ To compress refrigerant gas into liquid under high pressure;

◆ To evacuate the compressed refrigerant from the evaporator to the condenser;

◆ To transfer heat from inside the passenger compartment to outside by circulating air flow through the air-conditioning system.

Image source:

▶ Small volume and light weight, easy to install and maintain.

▶ High power density, compact structure and low noise level.

▶ Low operating temperature, no shaft seal, no oil leakage problem and long service life.

▶Smooth start-up performance due to no inertia load during startup, which can ensure the normal operation of all kinds of devices connected to the compressor motor, such as motor starter and filter solenoid valve etc..

7. On Board Charger (OBC)

The OBC is a key component that converts the AC input from the grid into DC and determines the charging power and efficiency of an electric vehicle. It monitors battery voltage and current, and manages communication between the vehicle and charger.The OBC has three main functions:

◆ It converts the AC current from the grid to DC current for charging;

◆ It regulates the charging power according to the voltage, amperage and temperature of the battery pack;

◆ It protects against overcharging, overheating or short circuiting;

8. DC-DC Converter

The DC-DC converter is an important high voltage component of electric vehicles, as it converts high voltage DC power supply to low voltage and vice versa. The most common type of converter used in EVs is a buck-boost converter, which has many different applications depending on what kind of system you need it for.The main functions of a DC-DC converter include:

◇ Supplying power to electronic circuits or other devices such as interior lights, wiper motor, fans etc.;

◇ Adjusting input voltage or output voltage as required;

◇ Connecting different voltages together;

◇ Stabilizing the voltage, changing unregulated voltage into regulated voltage;

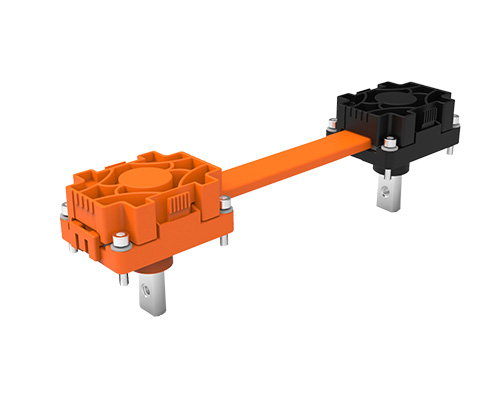

9. Manual Service Disconnect (MSD)

The electric vehicle is equipped with a MSD that can be used to safely disconnect the high voltage battery pack from the vehicle. MSD is recommended for use in situations such as when require access to the battery pack for safety reasons. MSD also has applications for maintenance and repair, where access to the high voltage components must be controlled by an authorized technician.A high voltage interlock loop (HVIL) is integrated into the MSD to ensure that all high voltage circuits are deenergized before the disconnecting device is opened. The HVIL is a short circuit protection device that activates when the voltage exceeds a pre-determined level.

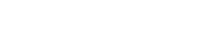

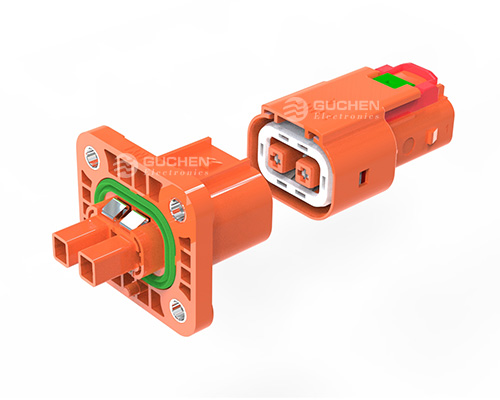

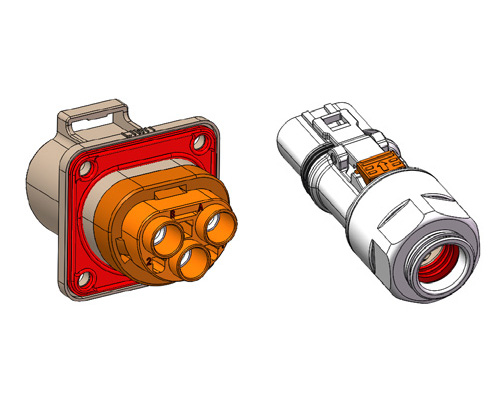

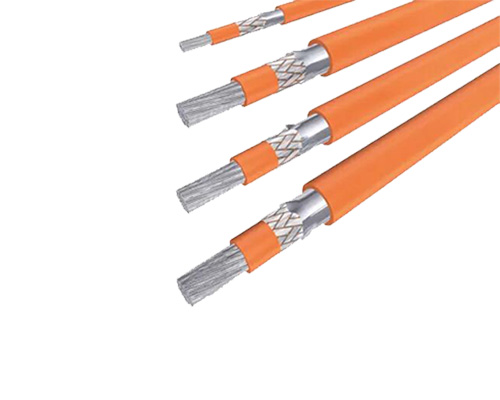

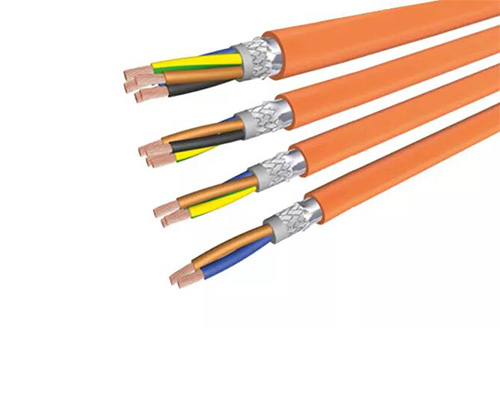

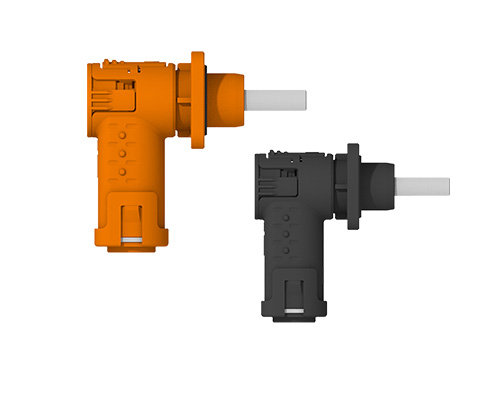

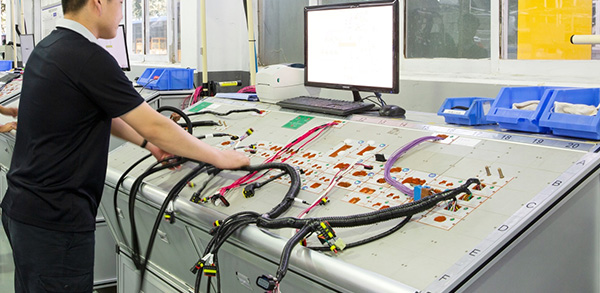

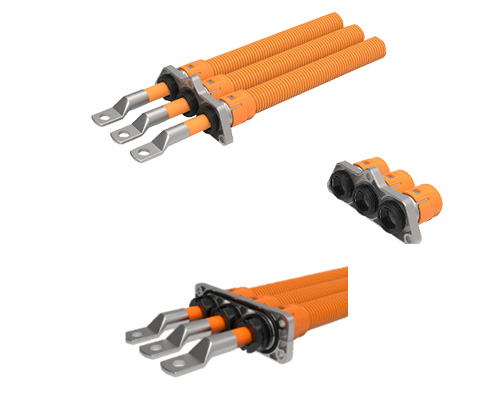

10. High Voltage Wiring Harness

The high-voltage wiring harness is a critical part of the drivetrain system in an electric vehicle (EV). It carries power between the battery pack and motor controller, as well as other high voltage components. In addition to carrying power, this harness may also include circuits for communication between components of the drive train system. It must be able to carry high voltage current, withstand high temperatures, and resist corrosion from road salt or other harsh conditions.High voltage wiring harness includes cables made from copper/aluminum conductors insulated by XLPE or silicone rubber jackets.

11. Charging Port

The charging port is the interface between the EV and a charging station. It allows the EV to communicate with a charging station via EV charging cable, receive power from it, and communicate with the grid.Type 1 is commonly used in North America manufacturers such as Chevrolet Volt, Ford Focus Electric, Nissan Leaf etc., while Type 2 CCS is more common in Europe and other parts of the world. There are also other types of charging ports that are available on some models of electric vehicles, such as the Tesla Model S, which uses a proprietary charging port known as Supercharger, which allows for fast charging at a higher voltage than other EVs.

.jpg)

The high voltage components of an EV are critical to make a functional vehicle. They are also the most expensive part of an EV, which is why it's important to know what each one does and how they work together.

Message

If you are interested in our products, please fill in the message form below. Our sales representative will contact you within 24 hours.