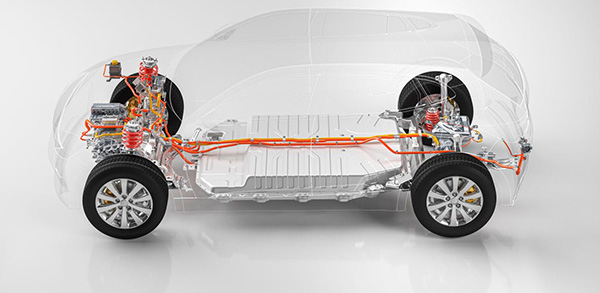

The Role of Shielding Design of High Voltage Wiring Harness for Electric Vehicles

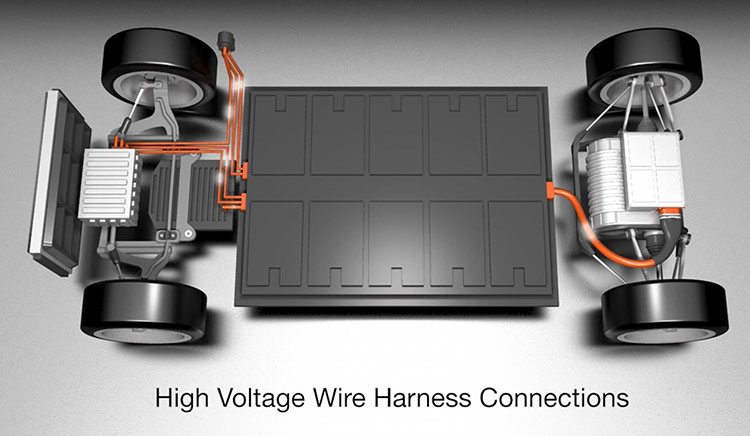

The shielding design includes:

◆ the shielding of the high voltage cables

◆ the shielding of the joint between the HV cable and connector

◆ the shielding of the high voltage connectors

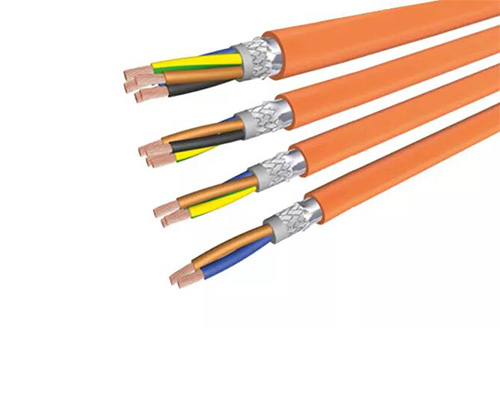

The Shielding of the High Voltage Cables

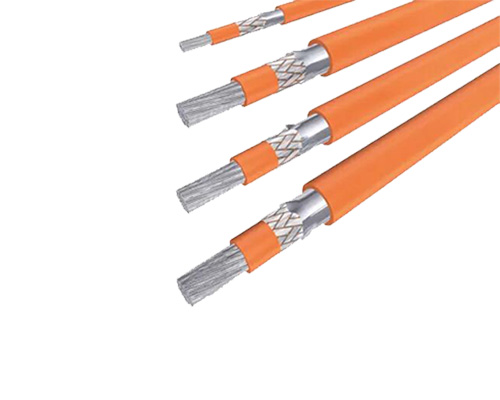

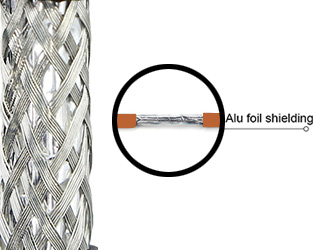

HV cables are mainly composed of four parts: conductor, insulation, shielding and sheath. The shield of the cable is responsible for blocking electromagnetic interference (EMI) and radio frequency interference (RFI). It also prevents leakage currents from being generated between adjacent cables. Therefore, it plays a very important role in cable design.The structure of the high voltage cable shield is generally divided into two types: tinned-copper wire braid shield and aluminum foil tape shield.

The role of the copper wire braid:

-- Shielding against electromagnetic interference;

-- Eliminate the shielding effect of the surface potential of the high-voltage cable, and eliminate the induced electricity;

-- The shielding function of safety protection. Copper wire is braided outside the main core insulation and in good contact with the ground core, which can respond to the leakage situation in time.

Aluminum foil shielding provides 100% coverage. 100% coverage is only a physical property, and it does not mean that metal foil shielding can shield 100% of electromagnetic interference. It is very effective at shielding both high and low frequency interference. They are lighter, less bulky, and generally add less cost to a cable or wire assembly than braided shields.

In complex multi-core shielded cable constructions, the core conductors are commonly covered with a single-layer or double-layer aluminum foil tape as an external sheath to ensure that the electrical properties meet the requirements of UL standards, and have outer braided shield. This is combined shielding. Combined shielding contains multiple shielding layers or uses multiple shielding methods, which has higher efficiency over a wider frequency spectrum. At the same time, it also plays an important role in preventing moisture penetration into inner conductor insulation material during usage.

The shielding tape also has two functions: one is to protect against electromagnetic interference as in single-layer braiding; another is to prevent penetration of moisture and water vapor into cable cores from outside environments. In addition, it also has an important role in improving mechanical properties such as cable bending resistance and tensile strength; therefore, it should be used properly according to relevant specifications.

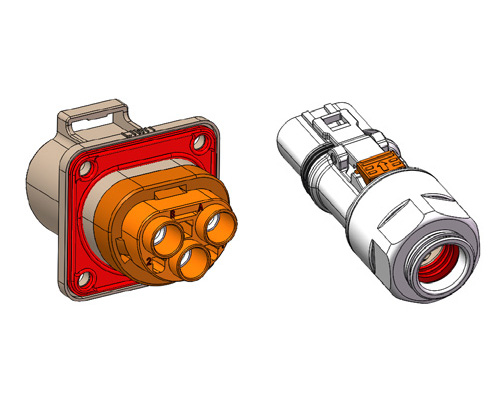

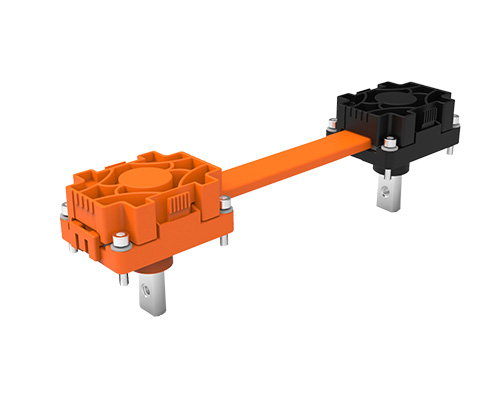

The Shielding of the Joint Between the HV Cable and Connector

The shielding at the junction generally uses a shielding ring. The size of the shielding ring varies according to the wire diameter of the high-voltage wire harness, and professional equipment is required for crimping.Copper, tinned copper or bronze tapes with a width of 13~17mm and a thickness of 0.1~0.15mm can also be used to wrap around the junction instead of the shielding ring, which reduces the crimping equipment and saves the investment of the shielding ring mold.

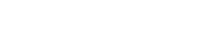

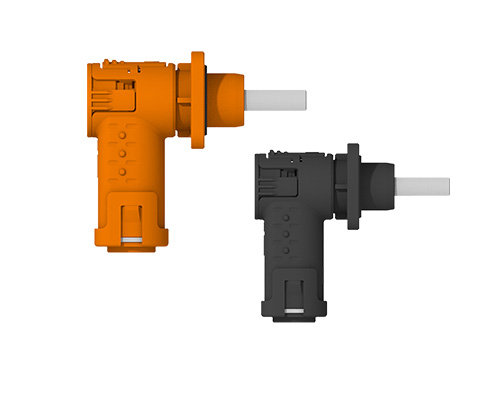

The Shielding of the EV HV Connectors

The electromagnetic shielding is an important feature of high voltage connectors. It is also one of the most complicated part of connector design. The shield must be able to withstand extreme mechanical forces and provide a high level of electrical protection. It must also be easily removable for maintenance, service and repair work.

What factors should be taken into account in terms of shielding design of EV connector?

Automotive industry has strict requirements for electromagnetic shields, such as temperature resistance and durability.

● the appearance of electromagnet shields

● the types of materials used for shielding purposes

● the size, thickness, shape and structure of contacts and housings

All these factors determine how much electromagnetic interference they can block, and have an impact on their shielding effectiveness. They must be taken into account during design and manufacturing processes when creating an effective shield design that meets industry standards.

The important role of electromagnetic shielding in high voltage connectors:

▶ To prevent external interference, which increases the reliability of the HV connector and reduces the failure rate.

▶ To improve the performance of the connectors in harsh environments.

▶ To withstand strong electromagnetic fields and ensure reliable power transmission between an electric vehicle and its charging station.

Message

If you are interested in our products, please fill in the message form below. Our sales representative will contact you within 24 hours.