Why is Temperature Rise Control so Important in Energy Storage Connector Design?

In recent years, with the development of renewable energy technology, Battery energy storage systems (BESS) has been widely used in the field of power supply and smart grid. They enable the use of renewable energy sources for both primary and secondary applications, such as providing backup power supply. BESSs also enable operators to reduce their dependence on fossil fuel-powered plants by storing excess electricity generated during peak hours when electricity prices are high and releasing it during off-peak hours when electricity prices are low.

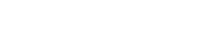

Secure Connections for Energy Storage Systems

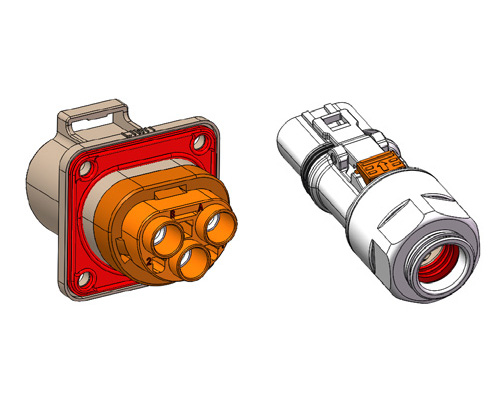

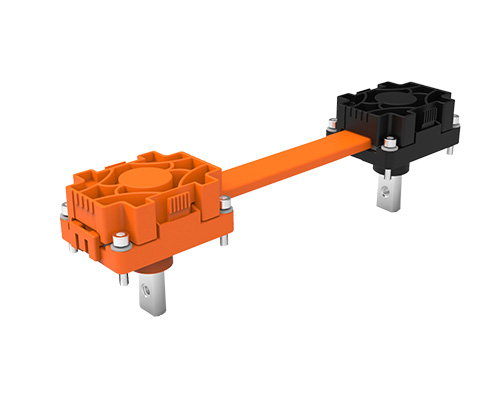

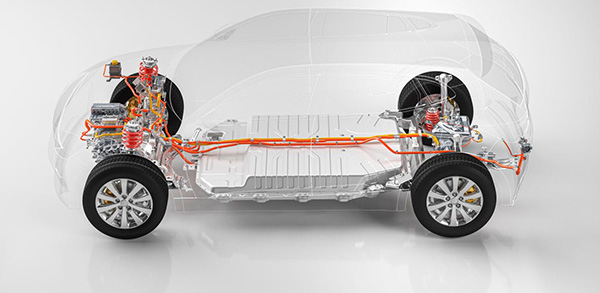

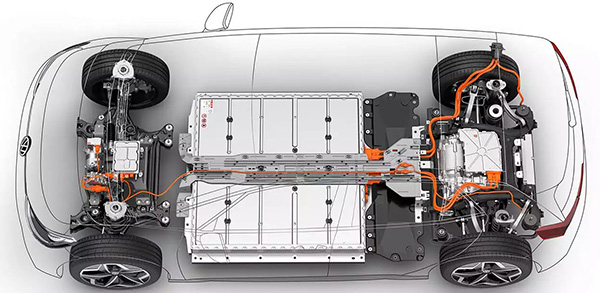

The connections between battery packs matter. Why? Because these connections can make or break your energy storage system’s reliability and efficiency. Without secure connections between cells, problems will occur and the battery pack may need replacing sooner than expected.Batteries are the heart of any energy storage system. They provide the power to store electricity, which can then be used when needed. They are placed together in batteries racks or modules that often contain hundreds or thousands of individual cells. Each cell has its own protection circuit, which protects against short circuits and other hazards. Connecting these cells together requires an interconnect system that connects all these protection circuits together so that they work like one large battery system. These cells connections are often made by using battery pole connector, bus bar connector or lug connector. These connectors are designed to prevent any movement between the cells. They also provide a low resistance path for the current to flow from one cell to another. This can reduce the voltage drop across each cell and increase total energy storage capacity of the battery bank.

From 2012 to 2022, there have been 54 fire and explosion accidents in energy storage power stations around the world. This may be related to the system defects of the energy storage lithium battery itself, such as short circuit and thermal management failure; it may also be related to the external thermal management system and connection system. For example, the temperature rise of the energy storage connector will have a certain impact on the battery.

When the energy storage battery pack is charging and discharging, the large current transmitted will cause the connector to generate thermal effects. Once the temperature of the connector rises above the temperature of the battery, it will be conducted to the battery terminal, thereby affecting the internal stability and electrochemistry of the battery. ability. When the internal temperature of the battery continues to rise and exceeds the ignition point of the electrolyte, the battery will explode. Since the battery packs are connected in series/parallel, whether the connectors can be used safely will ultimately affect the entire energy storage system.

What Causes Temperature Rise?

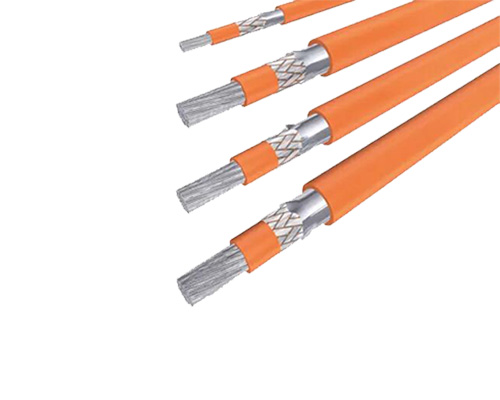

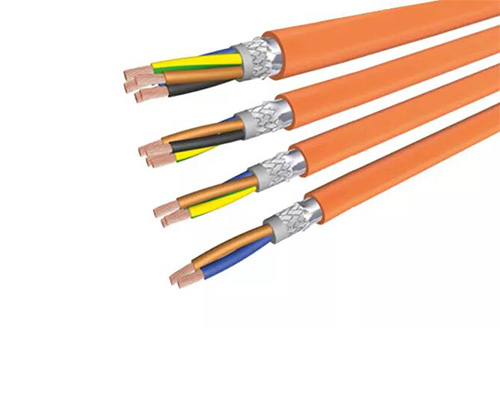

◆ The resistance of the wiring between each battery terminal and another terminal on another battery.The higher this resistance, the higher the potential for temperature rise. The resistance increases with longer lengths of HV wire harness and decreases with thicker wire gauges (i.e., lower AWG). You should keep wires as short as possible and use as large a gauge as practical for your application.

◆ Current

When the load current is too high, the temperature of the battery energy storage connector will increase greatly because of the large current flowing through it. Therefore, when designing the system, you should take into account the maximum load current so as not to exceed this limit. If you have already exceeded this limit and the temperature rises sharply, you must stop using it as soon as possible so that it does not damage other components or cause accidents.

The other causes include:

◆ Short circuit

If there is a short circuit between two terminals of a battery, this will allow high current flow through the connector and generate large amounts of heat from resistance in the metal wires.

◆ Incorrect polarity

If you connect a battery with reversed polarity (negative terminal connected to positive terminal), it will cause high currents to flow through the connector and generate lots of heat.

The Importance of Temperature Rise Control

Temperature rise control is an important aspect of connector design. When designing a BESS connector, it is essential to consider how heat will affect the connector and its performance. Many connectors are subject to thermal cycling, which can cause damage to components if not properly addressed. The following are some examples of why temperature rise control is so important in energy storage connector design:

◆ Connector failure: Heat is one of the biggest causes for connector failure in energy storage systems. When connectors fail due to heat exposure, it can be difficult or impossible for users to repair them on site without specialized equipment or training. In addition to being difficult to repair on site, connectors that fail due to excessive heat exposure may also create safety hazards because they no longer perform their intended function — such as protecting equipment from overcurrents or short circuits.

Temperature Rise Control for BESS Connectors

When connecting more than one energy storage device together, you need to be aware of the temperature rise caused by the increase in current flow. This can cause overheating if not controlled properly. Therefore, it's important that you take steps to control any temperature rise that may occur. The temperature rise control of energy storage connector plays an essential role in energy storage system reliability and safety.The temperature rise control technology that Guchen electronic adopts is generally divided by three levels:

◆ Low electrical resistance

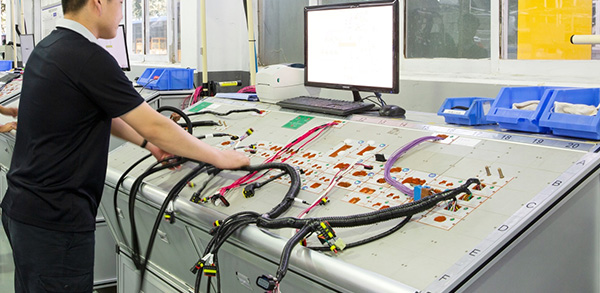

The temperature rise is mainly related to the resistance. The connectors are designed with low resistance, which means that there is less voltage drop when charging or discharging batteries at higher currents. The main factors affecting the resistance are the material, coating, surface film of the contact, and the positive pressure, current and voltage after connection. The full inspection of resistance is a necessary measure. Guchen Electronic mainly controls the manufacturing end and the inspection end; and we must continue to do a good job on the defect rate feedback to improve the manufacturing process. Guchen battery energy connectors have been tested for reliability under extreme temperature conditions and have been proven to withstand high temperatures without causing damage or failure in your system.◆ Selecting a high-quality contact material

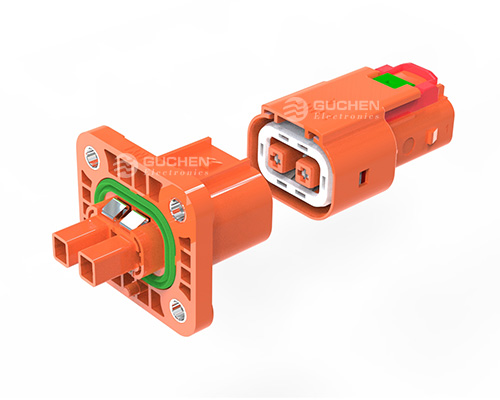

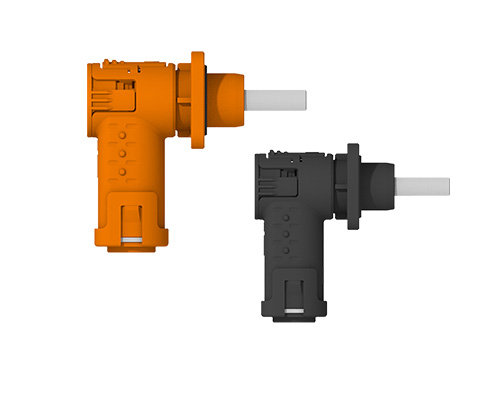

The temperature rise control of the connector mainly focuses on the contact material selection and the structural design. The terminal technology with independent intellectual property rights of the company is adopted, and the contact surface between the inside of the terminal and the pin is kept at the optimal area, which effectively reduces the contact resistance, reduces the overcurrent density, and reduces the current temperature rise; Guchen blind plug energy storage connector adopts materials with excellent electrical conductivity, which can effectively improve the terminal's electrical conductivity and temperature rise control capability, aiming to provide a safer, more reliable and more flexible chemical energy storage connection solution.

◆ Premium connector design

To solve the temperature rise problem, Guchen connectors use metal materials with low resistance and high conductivity as much as possible; at the same time, the product design process is equipped with heat dissipation solutions. Multiple surfaces are designed in a corrugated fan shape, which improves the heat dissipation function.

Message

If you are interested in our products, please fill in the message form below. Our sales representative will contact you within 24 hours.