Electrical Contact Reliability of EV Connectors and the Application of Copper Materials

Copper materials play a central role in EV connectors. Their properties directly affect the conductivity, thermal conductivity, mechanical strength, and long-term reliability of connectors. This paper systematically elaborates on the functions and structural design of contact parts, copper material characteristics and applications, the theory of contact resistance and wear mechanisms, and the assurance of electrical contact reliability in automotive connectors, providing technical reference.

◆ Dynamic contact interfaces: Include structures such as elastic socket-pin mating, spring probes, and button contacts. For example, elastic sockets (slotted, leaf-spring, crown-spring, or wire-spring types) correspond to rigid pins, while elastic pins (twisted wire or leaf-spring types) correspond to rigid sockets.

◆ Static contact interfaces: Include separable terminations (such as butt or clamp connections) and non-separable terminations (such as soldering, crimping, insulation displacement, wire wrapping, and surface mounting).

The design of dynamic contact interfaces directly affects connector contact reliability, while static terminations ensure the stable connection between wires and contacts.

◆ Adhesive wear: When two contact surfaces are pressed tightly together, asperities may adhere. During relative motion, these adhesion points shear off, generating wear debris and causing surface damage.

◆ Abrasive wear: Hard particles entering the contact interface act like sandpaper, scratching and abrading the surfaces.

◆ Fatigue wear: Repeated contact stresses cause fatigue cracks on the surface. Over time, these cracks propagate, leading to material spalling and wear.

◆ Delamination wear: Contact surface materials undergo stress-induced stratification, and the upper layers peel away gradually.

◆ Fretting wear: Occurs between surfaces undergoing small-amplitude vibrations (1–100 µm). It is mainly caused by thermal expansion and contraction from temperature cycling and background vibration. Since automotive connectors operate under both vibration and thermal shock, fretting wear is common.

Key considerations include:

◆ Material stability and reliability: Contact materials must ensure stable normal force to maintain low contact resistance.

◆ Voltage and current stability: Contacts must operate normally under varying electrical loads.

◆ Thermal performance: Contacts must remain within the specified temperature range, including ambient temperature and self-heating.

◆ Robustness in harsh conditions: The design must account for vibration, oxidation, and fretting corrosion encountered during vehicle operation.

High-quality copper materials should be selected to meet requirements for conductivity, tensile strength, and elastic modulus, ensuring efficient and stable current transmission. The design should ensure stable normal force and maintain contact resistance at low levels, thereby enhancing reliability.

◆ Stamping stage: High-speed stamping machines punch thin metal strips into contact shapes (such as pins). Care must be taken to avoid twisting, cracking, or deformation.

◆ Electroplating stage: Metal coatings are applied to contact surfaces to enhance conductivity and corrosion resistance. Quality defects must be strictly monitored.

◆ Injection molding stage: Molten plastic is injected into molds to form contact housings. Defects such as “short shots” must be prevented, and insertion holes must remain clean and unobstructed.

◆ Final assembly stage: Electroplated pins are inserted into molded housings, either individually or in groups. Proper positioning and completeness of all pins must be verified, and connector mating dimensions checked.

The entire production process requires high manufacturing efficiency while ensuring consistent product reliability.

◆ Contact resistance measurement

◆ Insulation resistance and dielectric withstand testing

◆ Vibration and mechanical shock testing

◆ Solderability and stress corrosion testing

◆ Salt spray and humidity testing

◆ Temperature cycling and thermal shock testing

◆ Corrosive gas testing

These tests evaluate performance under different environmental conditions. For example, vibration testing assesses mechanical and electrical effects during vibration, especially intermittent current failures. Salt spray testing evaluates corrosion resistance of connectors, terminals, and coatings. Through rigorous testing, product quality and reliability are ensured, guaranteeing safe automotive operation.

Salt Spray Test of High-Voltage Connectors

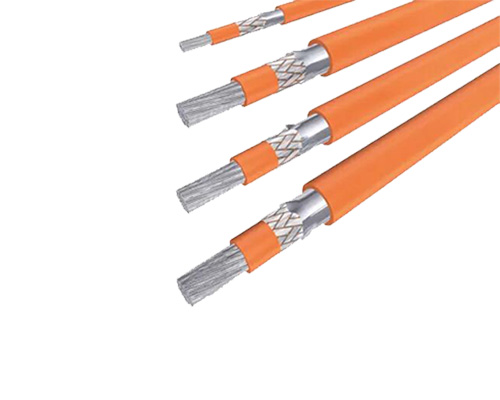

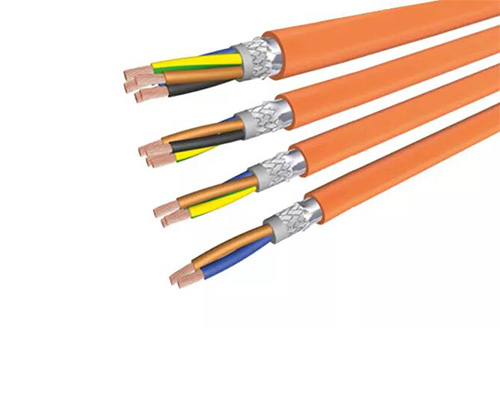

What Tests Do EV HV Wiring Harnesses Need to Do?

Key performance indicators include:

◆ Conductivity: Directly affects current transmission efficiency.

◆ Tensile strength: Prevents breakage under stress.

◆ Elastic modulus: Reflects stiffness.

◆ Yield strength: Indicates the stress at which plastic deformation begins.

◆ Poisson’s ratio: Describes the relationship between transverse and longitudinal strain.

◆ Elongation: Reflects ductility.

◆ Hardness: Affects wear and deformation resistance.

◆ Resistance to thermal stress relaxation: Ensures stability at high temperatures.

◆ Thermal conductivity: Governs heat dissipation efficiency.

◆ Coefficient of thermal expansion: Determines dimensional stability under temperature variations.

◆ Specific heat: Indicates heat absorption and release capacity.

In practice, conductivity, yield strength, resistance to thermal stress relaxation, and formability are particularly critical.

Table 2. Common Copper and Copper Alloy Grades, Properties, and Applications for Connector Contacts

Adding alloying elements such as Zn, Al, Sn, Mn, and Ni enhances strength but usually reduces conductivity. Therefore, material selection requires balancing conductivity, strength, formability, and stress relaxation resistance.

Copper materials form the foundation of connector performance. Through scientific material selection, optimized design, precision manufacturing, and rigorous testing, EV HV connectors can achieve high conductivity, high reliability, and long-term stability. With the advancement of new energy vehicles and high-frequency electronic devices, stricter requirements will be imposed on copper materials and contacts. Research into micro-contact interfaces, electrical contact stability, and wear resistance will become key technological directions.

1. Function and Structural Design of Contact Parts

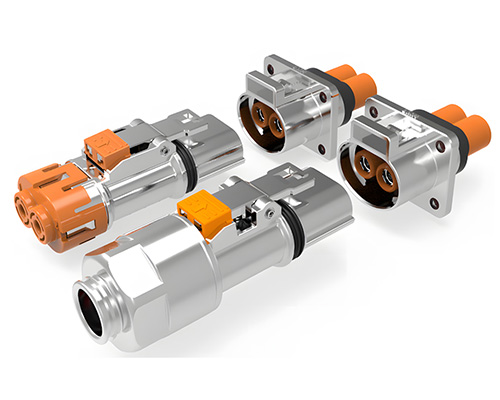

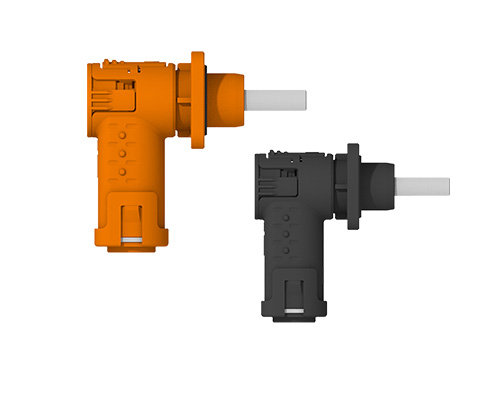

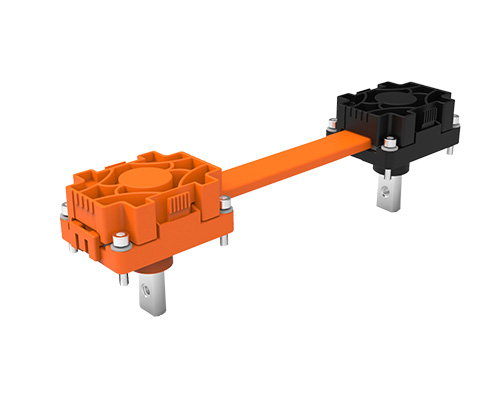

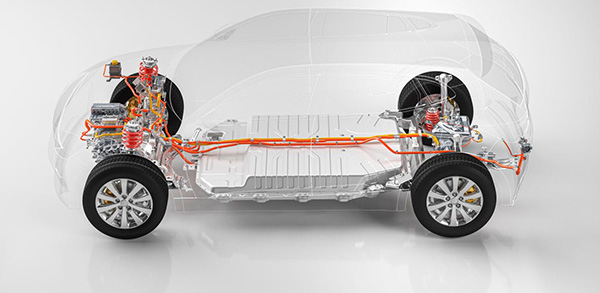

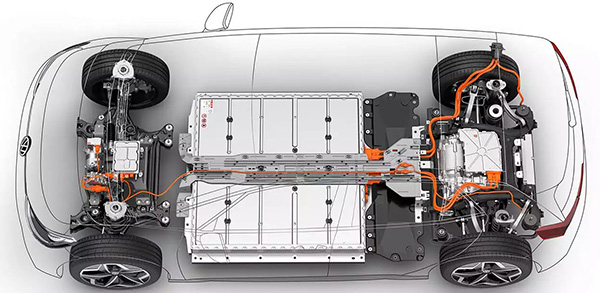

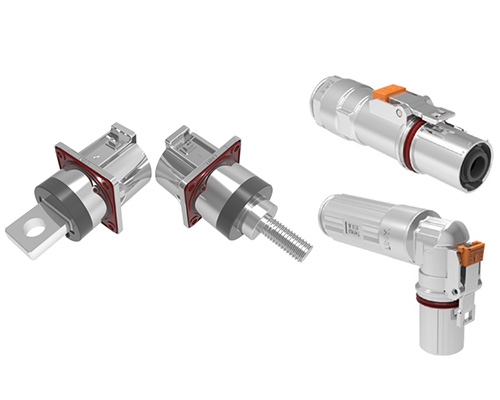

Contact parts are the key components of connectors. They are responsible for transmitting voltage or signals from the high voltage cable at the rear of the connector to the corresponding mating contact in the other connector, thereby completing the circuit. The separability of contacts distinguishes them from other electronic components. The front end of the contact forms a dynamic contact interface, while the rear end forms a static contact interface with wires, cables, or printed circuit boards.1.1 Types of Electrical Contact Interfaces

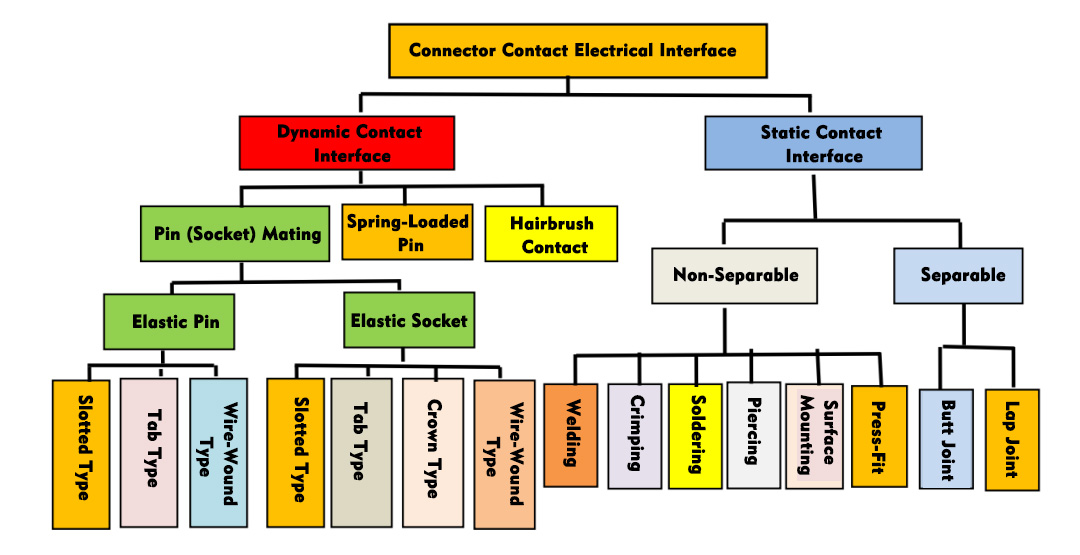

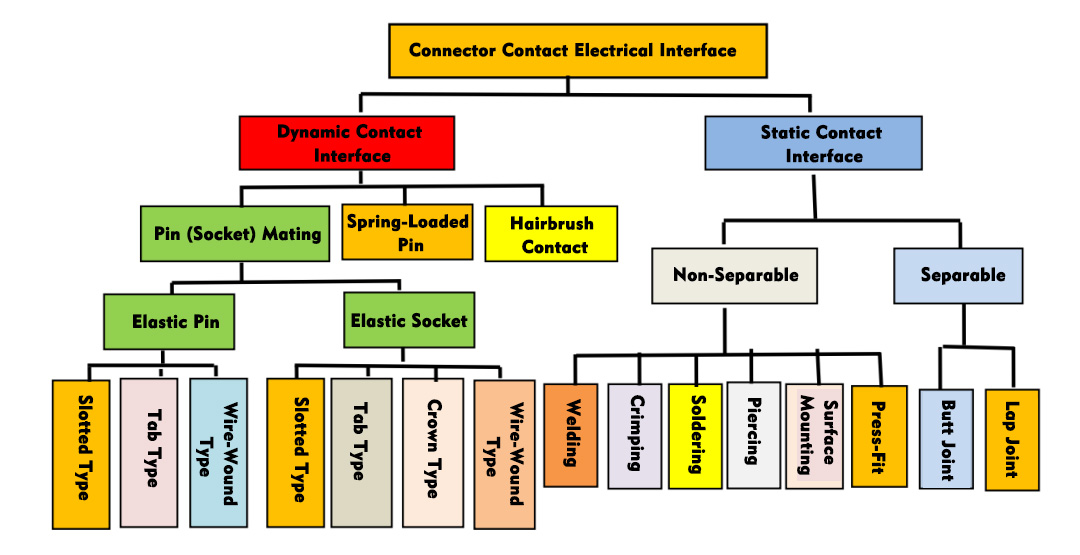

Electrical contact interfaces of connector contacts are divided into two categories: dynamic and static.◆ Dynamic contact interfaces: Include structures such as elastic socket-pin mating, spring probes, and button contacts. For example, elastic sockets (slotted, leaf-spring, crown-spring, or wire-spring types) correspond to rigid pins, while elastic pins (twisted wire or leaf-spring types) correspond to rigid sockets.

◆ Static contact interfaces: Include separable terminations (such as butt or clamp connections) and non-separable terminations (such as soldering, crimping, insulation displacement, wire wrapping, and surface mounting).

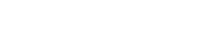

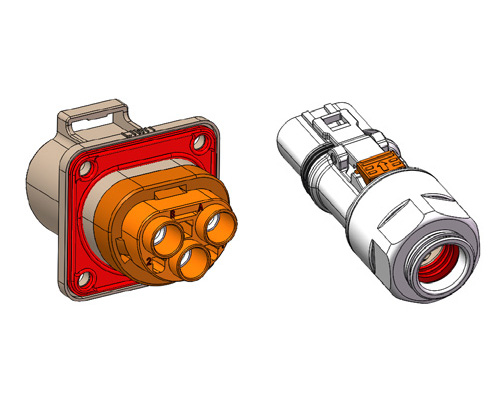

Figure 1. Classification of Connector Contact Electrical Interface Structures

The design of dynamic contact interfaces directly affects connector contact reliability, while static terminations ensure the stable connection between wires and contacts.

1.2 Failure Modes of Electrical Contacts

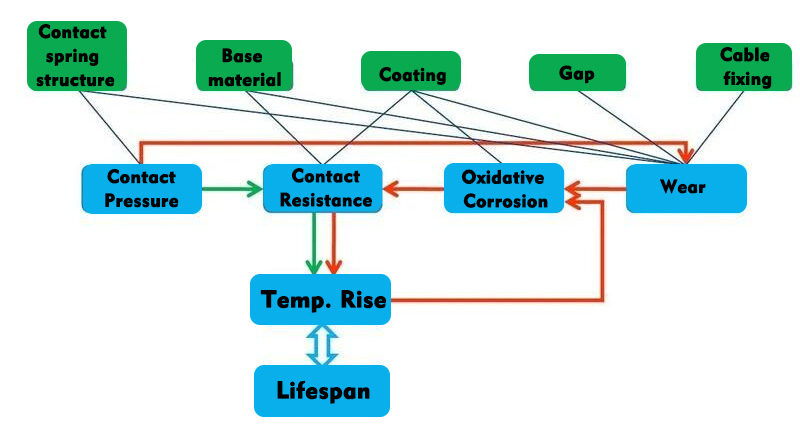

High voltage connectors play a crucial role in automotive electrical systems. However, compared with other types of connectors, automotive connector contacts are more prone to wear-related failures. This is mainly because automobiles operate under complex conditions such as vibration, shock, and temperature variations. Particularly in new energy vehicles (NEVs), the wear behavior of high-voltage connector contacts differs significantly from that of low-voltage connectors. High-voltage connectors in NEVs must withstand higher voltages and currents and harsher environments, leading to different wear mechanisms and degrees of deterioration compared to low-voltage connectors.1.3 Classification of Contact Wear

Contact wear in automotive connectors can be divided into five main categories:◆ Adhesive wear: When two contact surfaces are pressed tightly together, asperities may adhere. During relative motion, these adhesion points shear off, generating wear debris and causing surface damage.

◆ Abrasive wear: Hard particles entering the contact interface act like sandpaper, scratching and abrading the surfaces.

◆ Fatigue wear: Repeated contact stresses cause fatigue cracks on the surface. Over time, these cracks propagate, leading to material spalling and wear.

◆ Delamination wear: Contact surface materials undergo stress-induced stratification, and the upper layers peel away gradually.

◆ Fretting wear: Occurs between surfaces undergoing small-amplitude vibrations (1–100 µm). It is mainly caused by thermal expansion and contraction from temperature cycling and background vibration. Since automotive connectors operate under both vibration and thermal shock, fretting wear is common.

2. Assurance of Electrical Contact Reliability in EV HV Connectors

2.1 Key Points in Contact Design

In designing EV connectors, optimizing the structure and selecting high-quality raw materials are essential to improve contact reliability. Structural design must ensure stability and durability under different operating conditions, minimizing issues such as poor contact caused by vibration or shock.Key considerations include:

◆ Material stability and reliability: Contact materials must ensure stable normal force to maintain low contact resistance.

◆ Voltage and current stability: Contacts must operate normally under varying electrical loads.

◆ Thermal performance: Contacts must remain within the specified temperature range, including ambient temperature and self-heating.

◆ Robustness in harsh conditions: The design must account for vibration, oxidation, and fretting corrosion encountered during vehicle operation.

High-quality copper materials should be selected to meet requirements for conductivity, tensile strength, and elastic modulus, ensuring efficient and stable current transmission. The design should ensure stable normal force and maintain contact resistance at low levels, thereby enhancing reliability.

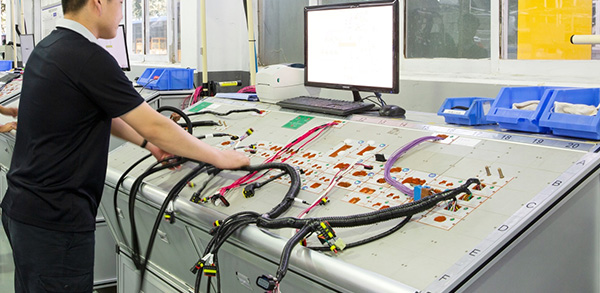

2.2 Production Process Control

Strict control during manufacturing is vital to ensuring connector quality.◆ Stamping stage: High-speed stamping machines punch thin metal strips into contact shapes (such as pins). Care must be taken to avoid twisting, cracking, or deformation.

◆ Electroplating stage: Metal coatings are applied to contact surfaces to enhance conductivity and corrosion resistance. Quality defects must be strictly monitored.

◆ Injection molding stage: Molten plastic is injected into molds to form contact housings. Defects such as “short shots” must be prevented, and insertion holes must remain clean and unobstructed.

◆ Final assembly stage: Electroplated pins are inserted into molded housings, either individually or in groups. Proper positioning and completeness of all pins must be verified, and connector mating dimensions checked.

The entire production process requires high manufacturing efficiency while ensuring consistent product reliability.

2.3 Reliability Testing

Strengthened reliability testing is essential to ensure electrical contact reliability. A comprehensive testing system should be established, including:◆ Contact resistance measurement

◆ Insulation resistance and dielectric withstand testing

◆ Vibration and mechanical shock testing

◆ Solderability and stress corrosion testing

◆ Salt spray and humidity testing

◆ Temperature cycling and thermal shock testing

◆ Corrosive gas testing

These tests evaluate performance under different environmental conditions. For example, vibration testing assesses mechanical and electrical effects during vibration, especially intermittent current failures. Salt spray testing evaluates corrosion resistance of connectors, terminals, and coatings. Through rigorous testing, product quality and reliability are ensured, guaranteeing safe automotive operation.

Salt Spray Test of High-Voltage Connectors

What Tests Do EV HV Wiring Harnesses Need to Do?

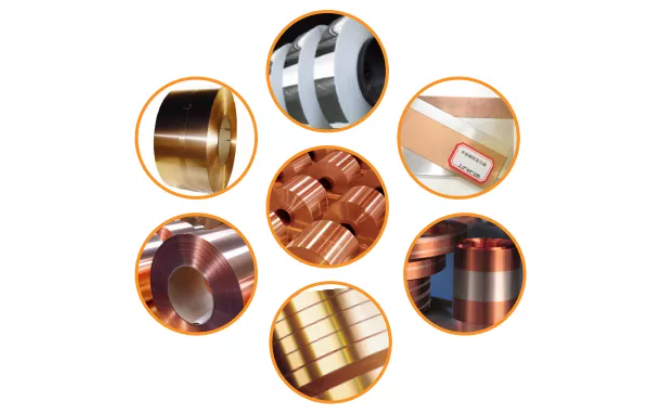

3. Impact of Copper Materials on Connector Performance

Copper is the base material for manufacturing connector contacts (commonly called terminals or pins). Its properties directly determine the conductivity, thermal conductivity, mechanical strength, dimensional stability, environmental resistance, formability, and plateability of connectors.Key performance indicators include:

◆ Conductivity: Directly affects current transmission efficiency.

◆ Tensile strength: Prevents breakage under stress.

◆ Elastic modulus: Reflects stiffness.

◆ Yield strength: Indicates the stress at which plastic deformation begins.

◆ Poisson’s ratio: Describes the relationship between transverse and longitudinal strain.

◆ Elongation: Reflects ductility.

◆ Hardness: Affects wear and deformation resistance.

◆ Resistance to thermal stress relaxation: Ensures stability at high temperatures.

◆ Thermal conductivity: Governs heat dissipation efficiency.

◆ Coefficient of thermal expansion: Determines dimensional stability under temperature variations.

◆ Specific heat: Indicates heat absorption and release capacity.

In practice, conductivity, yield strength, resistance to thermal stress relaxation, and formability are particularly critical.

3.1 Application Status of Copper Materials in Contacts

When selecting contact materials, factors such as surface quality, dimensional tolerance, conductivity, yield strength, elongation, resistance to thermal stress relaxation, fatigue strength, heat resistance, formability, corrosion resistance, plateability, and solderability must be comprehensively considered. Among these, conductivity, yield strength, resistance to stress relaxation, and formability are the most critical.Table 2. Common Copper and Copper Alloy Grades, Properties, and Applications for Connector Contacts

| Alloy Type | Common Grade | Yield Strength (MPa) | Conductivity (%) | Thermal Conductivity (W/m·K) | Characteristics | Applications |

| Pure Copper | C12200 | 250 | 79 | 340 | Deep-drawable, weldable, good high-temperature resistance | Wire connectors |

| Iron-Copper | C19400 | 470 | 64 | 260 | Good conductivity/thermal conductivity, high strength | Automotive connectors, lead frames |

| Tellurium Copper | C14500 | 250 | 85 | 355 | Excellent conductivity, corrosion resistance | High-current connectors, NEVs, photovoltaic connectors |

| Chromium Zirconium Copper | C18150 | 600 | 85 | 330 | Conductive, thermal conductivity, stress relaxation resistance, machinable | Automotive connectors, lead frames |

| Brass | C26000 | 300 | 28 | 126 | Versatile properties | Military and civilian use (cartridges, decorative items) |

| Tin Brass | C42500 | 610 | 16 | 120 | High cold hardness, low friction | Automotive electrical connector springs |

| Phosphor Bronze | C51100 | 580 | 22 | 84 | Stamping, cold bending, high thermal stress relaxation resistance | Signal connectors (crimped/compatible pins) |

| Phosphor Bronze | C52100 | 700 | 13 | 62 | High strength, thermal stability | Signal connector elastic contacts |

| Beryllium Copper | C17200 | 1090 | 25 | 105 | High strength, stress relaxation resistance, excellent overall performance | High-reliability connector springs, wire-spring sockets, stranded pins |

| Nickel-Tin Copper | C72500 | 500 | 11 | 55 | Fatigue and corrosion resistance | Telecommunications |

| Nickel-Silicon Copper | C70250 | 800 | 42 | 180 | High strength, high-temperature stress relaxation resistance | Connector elastic contacts, lead frames, springs |

| Nickel-Cobalt-Silicon Copper | C70350 | 900 | 45 | 200 | Superior properties compared to C70250 | Beryllium copper replacement for automotive/electrical connector contacts |

| Titanium Copper | CuTi3.5 | 900 | 13 | 50 | High strength, high-temperature stress relaxation resistance | Beryllium copper replacement for high-reliability elastic contacts |

Adding alloying elements such as Zn, Al, Sn, Mn, and Ni enhances strength but usually reduces conductivity. Therefore, material selection requires balancing conductivity, strength, formability, and stress relaxation resistance.

Copper materials form the foundation of connector performance. Through scientific material selection, optimized design, precision manufacturing, and rigorous testing, EV HV connectors can achieve high conductivity, high reliability, and long-term stability. With the advancement of new energy vehicles and high-frequency electronic devices, stricter requirements will be imposed on copper materials and contacts. Research into micro-contact interfaces, electrical contact stability, and wear resistance will become key technological directions.

Message

If you are interested in our products, please fill in the message form below. Our sales representative will contact you within 24 hours.