UQD Blind-Mate Connectors: Driving Liquid Cooling Standardization

The standardization of UQD (Universal Quick Disconnect) connectors initially originated from Intel under the framework of the Open Compute Project (OCP), aimed at addressing the industry pain point of the lack of unified standards for quick connectors in data center liquid cooling systems. As early as 2019, Intel launched the UQD standard initiative within the OCP community, collaborating with the industry to develop the UQD Specification Rev 1.0, which standardized the key mechanical dimensions and basic performance requirements of quick connectors, ensuring physical interoperability across different manufacturers’ products.

Following the release of this open standard, major international fluid connector manufacturers—including Danfoss, CEJN, Stäubli, and CPC—launched products compliant with the OCP UQD specification, initially addressing the challenge of interface unification. However, the early OCP standards primarily focused on mechanical dimensions, leaving differences in sealing performance, flow characteristics, and material compatibility between manufacturers. As a result, although products from different brands could physically connect, their interchangeability and reliability in practical applications remained limited.

In August 2025, Intel officially established the Universal Quick Disconnect Interoperability Alliance, marking a new stage in UQD standardization. The alliance’s first certified partners include Envicool, Danfoss, Readore Technology, Lankelec, and General Connectivity, five suppliers within the liquid cooling ecosystem. Over a year, 250 samples underwent 32 test projects and thousands of test cycles, ultimately achieving true cross-brand UQD interoperability. Unlike early OCP standards, which only unified mechanical dimensions, the Intel alliance conducted in-depth compatibility testing, identifying and resolving differences in spring stiffness, compression spacing, and sealing ring materials, and established stricter testing standards and processes for interchangeability.

Chen Baoli, Vice President of Intel’s Data Center and AI Group and General Manager of China, stated that the alliance effectively addresses industry pain points, transforming liquid cooling from “usable” to “highly usable” and laying a solid foundation for large-scale deployment of liquid cooling technology. We believe that the establishment of this standardization alliance will significantly reduce operational complexity in data centers, enhance system reliability, and promote the maturation of the liquid cooling industry.

Blind-mate UQD represents the future development trend of data center liquid cooling technology, offering clear advantages in automation, operational efficiency, and system reliability compared with non-blind-mate products. According to connection methods, UQDs are classified into Blind Mate (UQDB) and Hand Mate types, which differ fundamentally in connection mechanism and application scenarios.

UQDB uses an automatic connection mechanism, enabling rapid connection without precise alignment, with a radial misalignment tolerance of ±1 mm. Its design is more complex but significantly improves operational efficiency. In contrast, UQD emphasizes connection accuracy and stability, requiring precise alignment to ensure proper sealing. Its structure is simpler but demands higher installation skill and experience. Blind-mate products are mainly applied in space-constrained or high-convenience liquid cooling cabinet scenarios, reducing time wasted due to alignment difficulties.

Automation: UQDBs reduce the need for manual intervention, maximizing system uptime and service continuity, whereas hand-mate products still require manual operation by technicians.

Operational Efficiency: UQDB Blind-mate connectors significantly shorten connection time and reduce the risk of human error, particularly in high-density data centers.

System Reliability: Blind-mate connectors minimize operational mistakes and mechanical damage risks through self-alignment and durable design, whereas hand-mate products rely more heavily on operator skill.

We believe that as data centers evolve toward intelligence and automation, and as AI and high-performance computing demand increasingly continuous operation, blind-mate UQDs will gradually become the mainstream choice, while hand-mate products will remain suitable primarily for cost-sensitive or lower-technical-requirement applications.

Following the release of this open standard, major international fluid connector manufacturers—including Danfoss, CEJN, Stäubli, and CPC—launched products compliant with the OCP UQD specification, initially addressing the challenge of interface unification. However, the early OCP standards primarily focused on mechanical dimensions, leaving differences in sealing performance, flow characteristics, and material compatibility between manufacturers. As a result, although products from different brands could physically connect, their interchangeability and reliability in practical applications remained limited.

| Specification | UQD02 | UQD04 | UQD06 | UQD08 | Priority |

| Maximum fluid loss (per connection/disconnection at 0 psi) |

0.020 ml | 0.025 ml | 0.035 ml | 0.070 ml | Required |

| Maximum working pressure | 100 psi | Required | |||

| Minimum burst pressure | 300 psi | Required | |||

| Minimum Cv value (water) | 0.25 | 0.8 | 1.6 | 2.5 | Required |

| Flow rating (water) | ≥ 0.55 GPM | ≥1.7 GPM | ≥ 3.0 GPM | ≥ 4.7 GPM | Recommended |

| Operating temperature range | 17°C – 65°C | Required | |||

| Transport temperature range | -40°C – 75°C | Required | |||

| Storage life | 5 years | Required | |||

| Service life | 10 years | Required | |||

| Connection/disconnection cycles | 5,000 times | Required | |||

| Maximum connection force | Supplier must publish connection force data relative to pressure | Required | |||

| Locking mechanism feedback | Visual, tactile and/or audible feedback | Recommended | |||

Figure 1: OCP standard requirements for temperature, lifespan, and flow rate

In August 2025, Intel officially established the Universal Quick Disconnect Interoperability Alliance, marking a new stage in UQD standardization. The alliance’s first certified partners include Envicool, Danfoss, Readore Technology, Lankelec, and General Connectivity, five suppliers within the liquid cooling ecosystem. Over a year, 250 samples underwent 32 test projects and thousands of test cycles, ultimately achieving true cross-brand UQD interoperability. Unlike early OCP standards, which only unified mechanical dimensions, the Intel alliance conducted in-depth compatibility testing, identifying and resolving differences in spring stiffness, compression spacing, and sealing ring materials, and established stricter testing standards and processes for interchangeability.

Chen Baoli, Vice President of Intel’s Data Center and AI Group and General Manager of China, stated that the alliance effectively addresses industry pain points, transforming liquid cooling from “usable” to “highly usable” and laying a solid foundation for large-scale deployment of liquid cooling technology. We believe that the establishment of this standardization alliance will significantly reduce operational complexity in data centers, enhance system reliability, and promote the maturation of the liquid cooling industry.

Figure 2: Intel Universal Quick Disconnect Interoperability Alliance

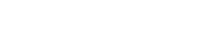

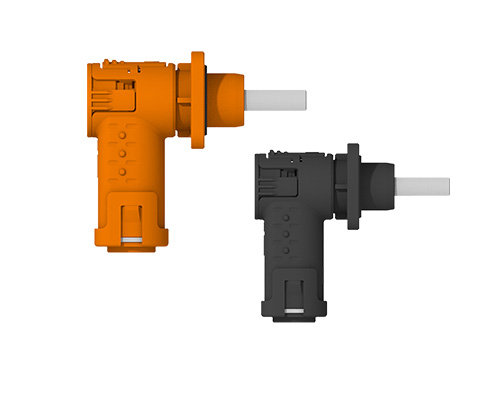

Blind-mate UQD represents the future development trend of data center liquid cooling technology, offering clear advantages in automation, operational efficiency, and system reliability compared with non-blind-mate products. According to connection methods, UQDs are classified into Blind Mate (UQDB) and Hand Mate types, which differ fundamentally in connection mechanism and application scenarios.

UQDB uses an automatic connection mechanism, enabling rapid connection without precise alignment, with a radial misalignment tolerance of ±1 mm. Its design is more complex but significantly improves operational efficiency. In contrast, UQD emphasizes connection accuracy and stability, requiring precise alignment to ensure proper sealing. Its structure is simpler but demands higher installation skill and experience. Blind-mate products are mainly applied in space-constrained or high-convenience liquid cooling cabinet scenarios, reducing time wasted due to alignment difficulties.

Figure 3: Hand Mate (left) vs. Blind Mate (right)

Automation: UQDBs reduce the need for manual intervention, maximizing system uptime and service continuity, whereas hand-mate products still require manual operation by technicians.

Operational Efficiency: UQDB Blind-mate connectors significantly shorten connection time and reduce the risk of human error, particularly in high-density data centers.

System Reliability: Blind-mate connectors minimize operational mistakes and mechanical damage risks through self-alignment and durable design, whereas hand-mate products rely more heavily on operator skill.

We believe that as data centers evolve toward intelligence and automation, and as AI and high-performance computing demand increasingly continuous operation, blind-mate UQDs will gradually become the mainstream choice, while hand-mate products will remain suitable primarily for cost-sensitive or lower-technical-requirement applications.

Message

If you are interested in our products, please fill in the message form below. Our sales representative will contact you within 24 hours.