Thermal Runaway Risk Prevention of Electric Commercial Vehicle

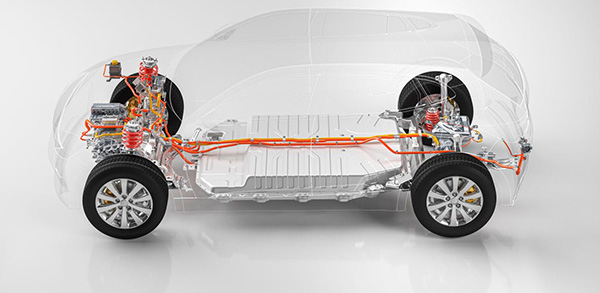

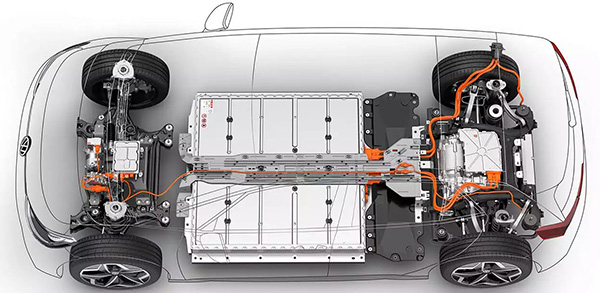

Currently, lithium iron phosphate batteries are mainly used in pure electric commercial vehicles and chemical energy storage systems. There are many reasons for tram fires, including fires during charging, self-ignition during driving and parking, quality problems with the battery and electrical equipment themselves, battery temperature rises, overcharging and over-discharging, and incomplete design of active fire protection measures. Thermal runaway of lithium batteries and the spread of thermal runaway of battery modules have become the main causes of fires and explosions in electric commercial vehicles. This article will analyze in detail the occurrence mechanism of thermal runaway, the causes of thermal runaway diffusion, and preventive measures.

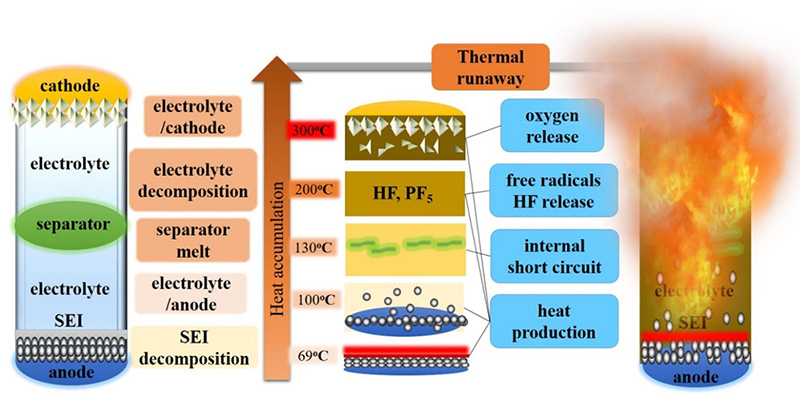

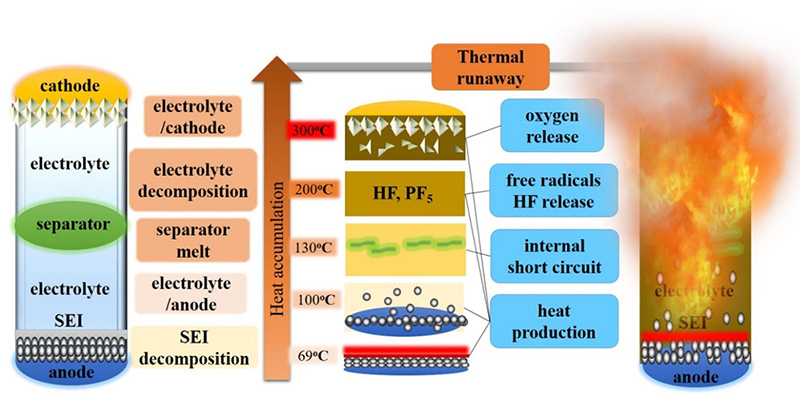

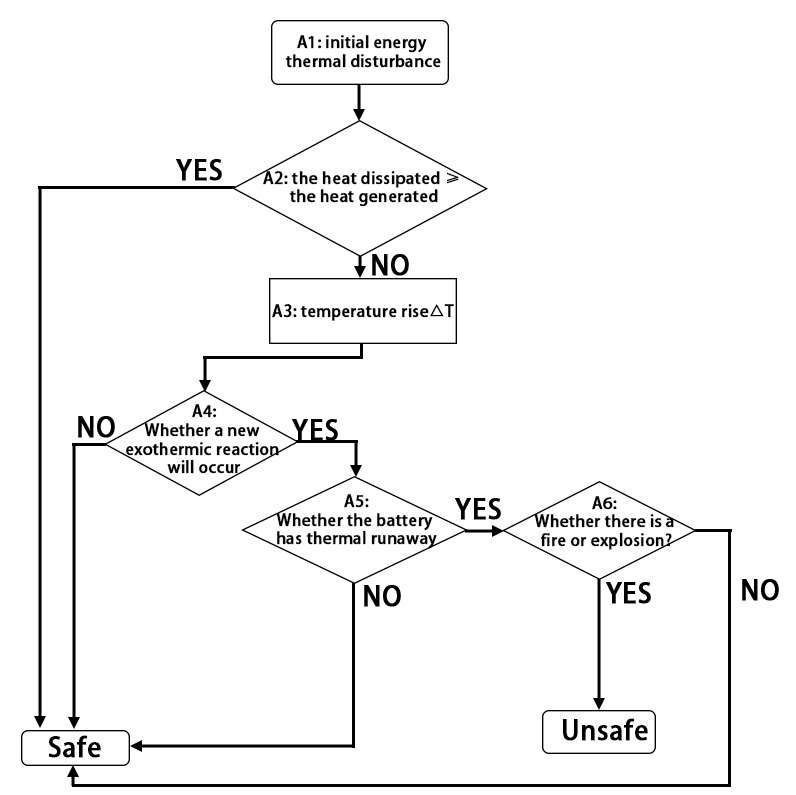

Figure 1 The process of disaster caused by thermal runaway of lithium-ion batteries

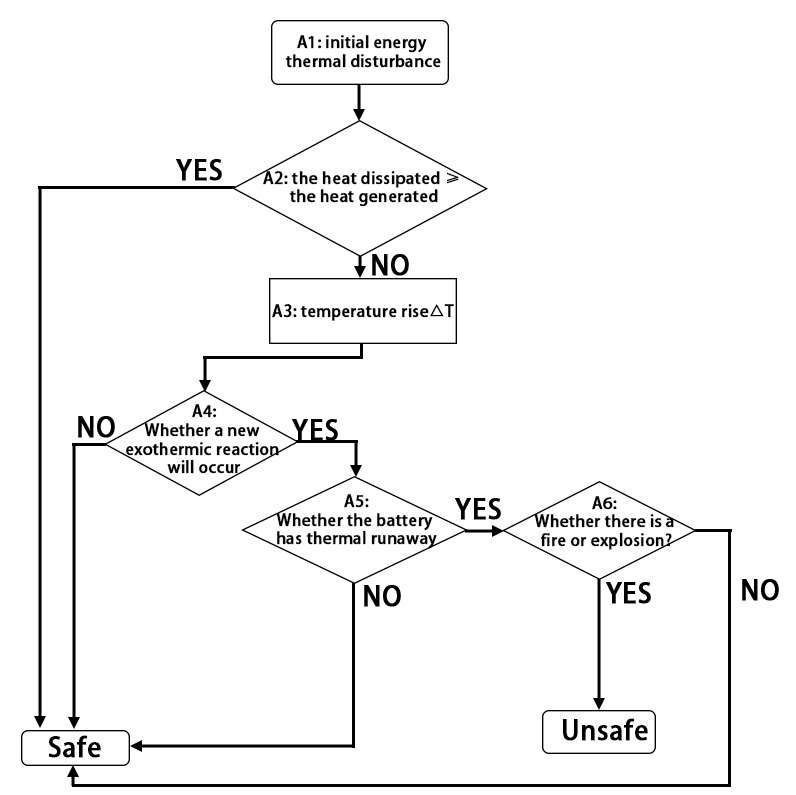

Thermal runaway results from the phased changes in the internal heat of the battery core, and its relationship with the battery core safety is shown in Figure 2:

The status description of the battery core after use can be divided into two states: non-failed and failed. If it has not failed, it means that the battery core can continue to be used if it meets the usage conditions, but if it fails, it means that the battery core is no longer suitable for continued use. The description of the failure state can be divided into two types: safe state and non-safe state: the safe state only shows abnormal capacity attenuation and abnormal internal resistance changes of the battery core; The unsafe state generally means that the battery core will produce uncontrollable energy release to the outside world.

When a battery core undergoes thermal runaway, its uncontrollable release of energy and toxic and harmful substances is defined as fire or explosion. At this time, it can be determined that a safety accident has occurred in the battery core.

The causes of thermal runaway can be divided into mechanical abuse (squeezing, acupuncture, collision, etc.), electrical abuse (external short circuit, overcharge, over-discharge), thermal abuse (loose contact of high-voltage connectors, electrode-collector contact failure), internal short circuit (diaphragm failure) and other factors cause the single battery to heat up violently. The high temperature and fire caused by a large amount of heat accumulation will cause thermal runaway in surrounding batteries. This causes thermal runaway to spread inside the battery pack.

◆ Thermal energy conduction: When the battery undergoes thermal runaway, the lateral heating generated by the front-side contact of the battery is very severe, causing the temperature gradient inside the heated battery to become larger in the thickness direction. Because the temperature of the battery front end reaches the thermal runaway triggering temperature, thermal runaway spreads.

◆ Electrical energy conduction: Thermal runaway of a single cell and the large-area shrinkage of the diaphragm cause an internal short circuit. The two can be causally related to each other, and will eventually cause the energy of the thermal runaway cell to drop rapidly. In the battery module parallel unit, other cells will discharge to the thermal runaway battery cell, causing the temperature of the thermally runaway cell to increase even more. At the same time, the cells close to the thermal runaway cells will discharge with greater power than the cells at the far end, causing their temperatures to rise rapidly, thus promoting the spread of thermal runaway.

◆ Mechanical energy conduction: The thermal runaway of a certain battery cell may affect the mechanical structure of the module, or its explosion may cause an instantaneous release of a large amount of energy, which may also cause a certain degree of mechanical damage to the surrounding cells. These Mechanical damage will increase the risk of failure of its surrounding cells, and in severe cases can directly lead to thermal runaway of its surrounding cells.

◆ Ejecta fire: When the battery thermally runs away, it will eject a mixture of high-temperature gases and particles. These gases are flammable and can easily cause fires. These high-temperature ejections and the flames generated by the their combustion will heat the surrounding batteries, thereby accelerating the spread of thermal runaway.

◆ Add temperature-affecting internal resistance materials (such as PTC or NTC materials) to the porous electrode ratio of positive and negative electrodes;

◆ Change the electrolyte Components to improve stability and reliability (such as developing solid electrolytes, adding functional additives, etc.);

◆ Developing new materials with functions such as flame retardancy, cooling, fire extinguishing, and oxygen isolation;

◆ Designing reliable directional and quantitative release strategies for energy and harmful substances, and cooperate with a structure that can withstand certain mechanical stress to avoid the impact of high-temperature ejections and flames on adjacent battery modules.

◆ Thermal diffusion protection design, module design should consider heat insulation and fire prevention measures to delay the time for the surrounding battery cells to ignite when a battery cell in the battery module experiences thermal runaway;

◆ According to the thermal diffusion coefficient of the battery core, design a reasonable battery spacing to avoid an increase in the temperature of adjacent battery cores and reduce the risk of thermal runaway caused by heat conduction;

◆ Adding a current limiting functional component to the circuit can quickly and accurately cut off the loop current when some loop current, voltage, and temperature are abnormal, which can effectively avoid electrical energy conduction;

◆ The battery modules are isolated in different areas within the battery system to reduce the speed of thermal runaway transmission and provide longer escape time for the occupants.

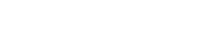

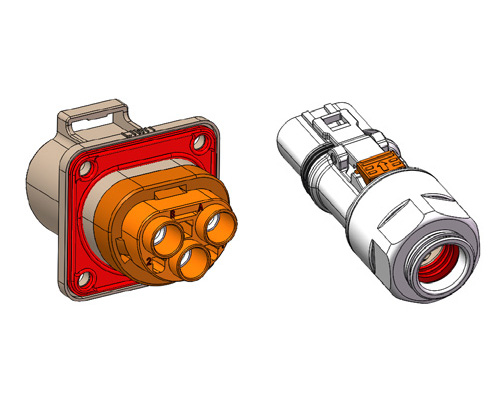

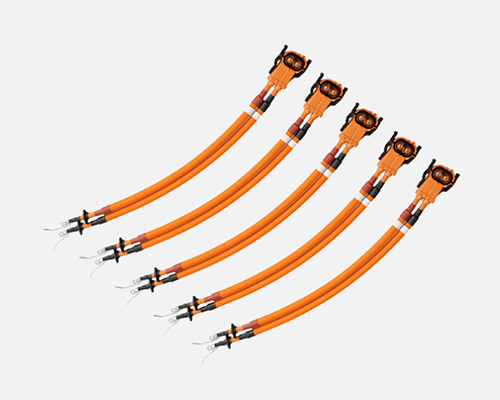

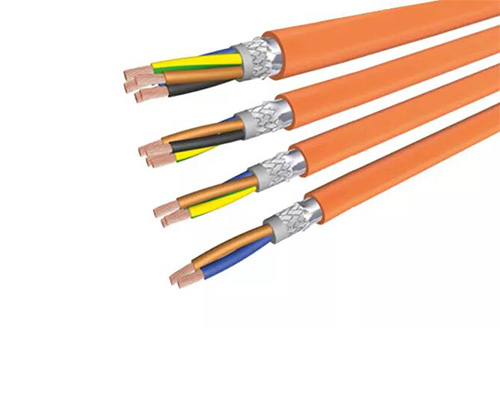

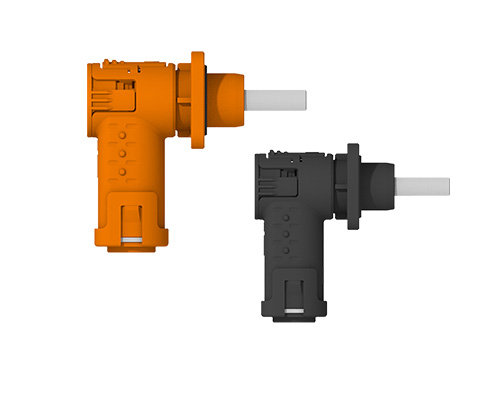

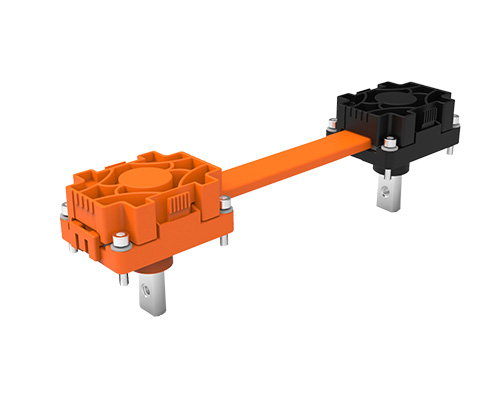

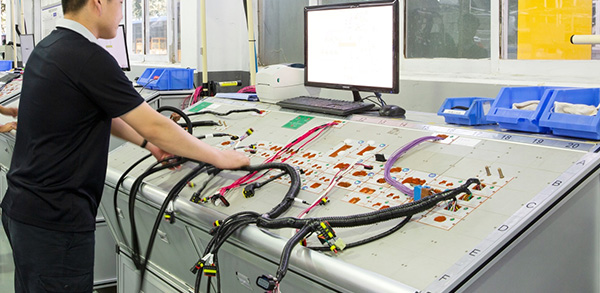

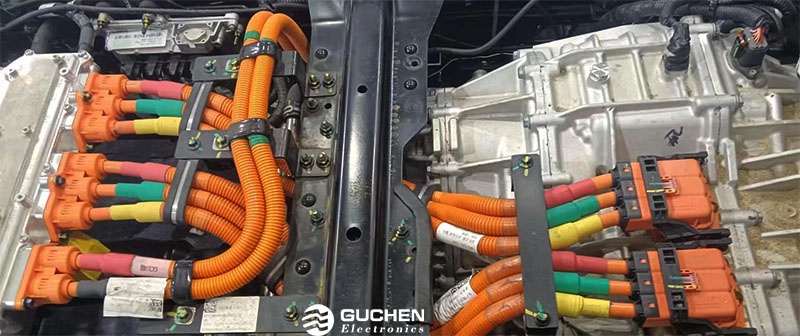

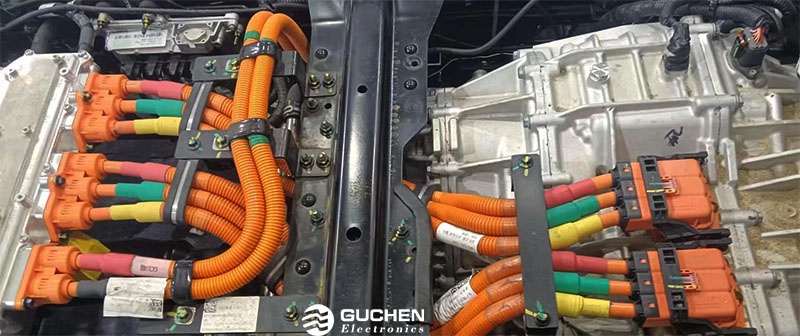

Figure 4 high voltage wire harness

Passive fire protection and flame retardancy mean that when designing the battery system, the components of the battery system should try to use materials with a relatively high flame retardant level or that cannot burn. The plastic parts inside the battery system must reach a certain flame retardant level, and the high and low voltage wire harnesses must use products with a higher flame retardant level. It is recommended that the EV high-voltage cables be selected with a temperature resistance of 125°C or above.

Active fire prevention and flame retardant design can be considered from two aspects: first, in the battery system design, add a fire prevention structure to prevent external flames from directly entering the inside of the box; second, in the power battery system design, add a nitrogen protection device inside the battery box.

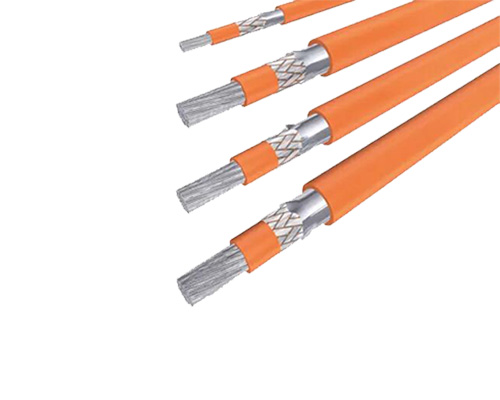

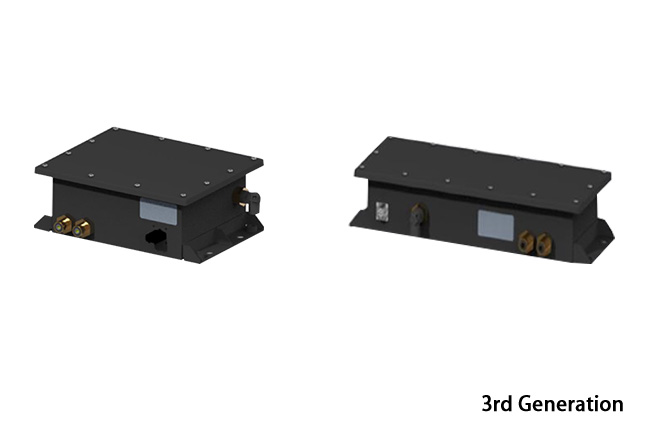

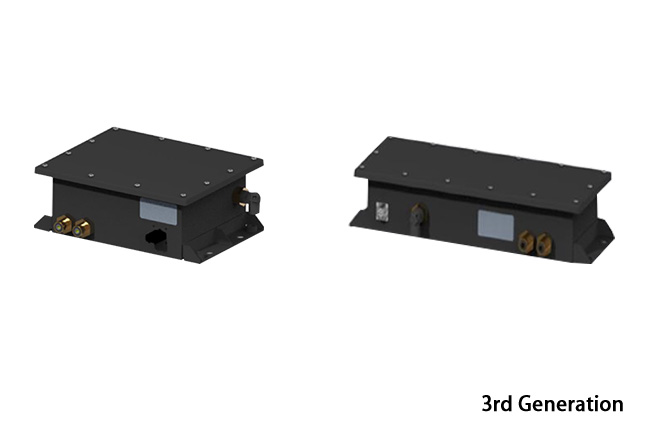

Figure 5 Guchen nitrogen fire protection device 3rd generation

Development background of nitrogen fire protection system

At this stage, lithium iron phosphate batteries are commonly used in new energy commercial vehicles around the world. Due to their fast burning speed and large number of ejected mass, lithium battery fires will not only produce poisonous gas, but also ordinary dry powder, foam or gas (heptafluoropropane) fire extinguishers cannot completely extinguish the fire. Therefore, special active fire protection and flame retardant devices for power battery boxes have become an urgent problem for the EV industry. Against this background, Guchen Electronic decided to jointly develop a lithium battery fire protection solution with Yutong Bus Corporation, a world leader in intelligent and new energy bus technology. After 3 years, we finally developed a patented, efficient and safe nitrogen protection system, and created a new fire prevention and flame retardant technology - 98% high purity nitrogen + MTV integrated integration technology.

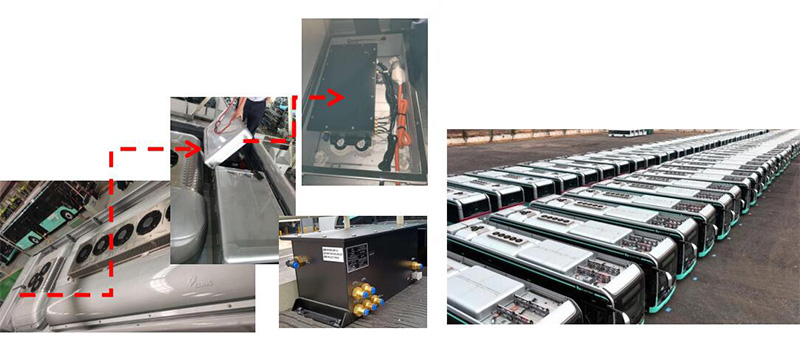

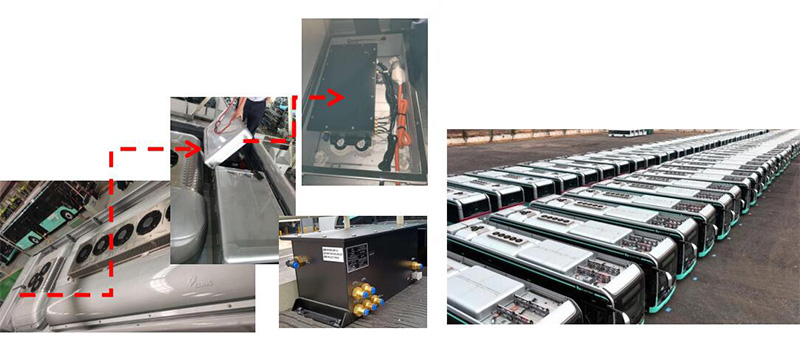

Figure 6 nitrogen fire protection device equipped on electric buses

Advantages of nitrogen protection system

It is equipped with industry-unique aviation-grade nitrogen separation system to extract high-purity nitrogen from our vehicle's compressed air in real time, with a nitrogen purity of over 98%. Then high-purity nitrogen is introduced into the battery pack in real time. In addition, the battery pack has a built-in multi-level detection system to maintain the battery pack in an anaerobic environment at all times.

High-purity nitrogen can effectively block air, leaving the inside of the battery in an oxygen-free environment, effectively reducing the risk of fire and greatly improving the safety protection level of the battery. The built-in sensor can monitor the nitrogen pressure value in real time 24 hours a day, realizing real-time nitrogen production and real-time nitrogen charging, so that the nitrogen pressure inside the battery box can be maintained at the set value for a long time. When internal faults such as internal short circuit and thermal runaway occur, the oxygen in the battery box is completely cut off to avoid combustion and ensure that the battery does not catch fire or explode.

Moreover, the system also combines the vehicle's MTV integrated integration technology to achieve early fire perception, intelligent judgment, and early intervention to protect the personal safety of electric commercial vehicles and passenger drivers to the greatest extent.

All designs can effectively and timely solve many problems such as fire and ignition of lithium ion batteries, and provide guarantee for the safe operation of all electric vehicles.

Our next major experiment is to see how the nitrogen protection system protects the lithium-ion battery safety when an internal short circuit or thermal runaway occurs inside the EV battery.

Figure 1 The process of disaster caused by thermal runaway of lithium-ion batteries

1.What is Thermal Runaway and Propagation?

1.1 Thermal runaway

Thermal runaway is an accident in which an electrochemical cell raises its temperature in an uncontrollable manner through self-heating. Currently, multiple standards have definitions for thermal runaway, see Table 1:| Standard | Definition of "Thermal Runaway" |

| GB/T 36276 | The phenomenon of uncontrollable temperature rise caused by exothermic reactions inside battery cells |

| IEC 62619 | Uncontrolled intensive increase in the temperature of a cell driven by exothermic reaction |

| UL1973 UL9540A |

The incident when an electrochemical cell increases its temperature through self-heating in an uncontrollable fashion. The thermal runaway progresses when the cell's generation of heat is at a higher rate than the heat it can dissipate. This may lead to fire, explosion and gassing. |

| A1 stage | The battery core will first generate initial energy thermal disturbance during use. The energy sources causing thermal disturbance include normal lithium ion charging and discharging chemical reactions inside the battery core, and internal abnormal chemical reactions (such as failure to meet the rated voltage, current, Internal violent reactions caused by temperature or the abuse of temperature heat conduction, internal violent reactions eventually caused by damage to external and internal mechanical structures, etc.), thus causing the battery core to generate heat. At the same time, the battery core will dissipate heat outwards, and some chemical reactions will be accompanied by heat absorption; |

| A2 stage | When the heat dissipated by the battery core + the heat consumed by the reaction ≥ the heat obtained by the battery core, the battery core is safe; |

| A3 stage | When the heat dissipated by the battery core + the heat consumed by the reaction < the heat obtained by the battery core, the battery core will generate a temperature rise ΔT. If ΔT does not bring about new exothermic reactions inside the battery core, the battery core is safe; |

| A4 stage | If there is a new exothermic reaction (such as the decomposition of SEI film, electrolyte, fluoride binder, and cathode active material, metal lithium deposited during overcharging reacts with the electrolyte to generate heat, the reaction between metallic lithium and the binder releases heat, combustion of combustible substances, etc.), when the internal reaction speed of the battery core caused by the heat released by these reactions is uncontrollable, the temperature of the battery core will rise uncontrollably, which will cause thermal runaway as we conventionally define it in the A5 stage. |

1.2 Thermal runaway propagation

When a thermal runaway battery generates more heat than it can dissipate, further heat build-up can result in fires, explosions, and gas releases. If in a battery system, thermal runaway in one cell causes thermal runaway in other cells, it is called thermal runaway propagation.2. Causes of Thermal Runaway and Thermal Runaway Propagation

2.1 Causes of thermal runaway

During the actual use of the battery core, its material reversible capacity, SEI impedance, electrolyte components, structural component physical indicators, etc. are a dynamic change process, which directly affects the dynamic changes of the battery core's charge and discharge curve, internal resistance, etc. If the actual usage conditions of the battery core (such as temperature limits, voltage limits, current values, etc.) are not dynamically adjusted to match them, this results in accelerated damage to the internal structure of the battery core and accelerated failure of some key raw materials, which is called battery abuse. Abuse often eventually leads to cell safety failure, known as thermal runaway.The causes of thermal runaway can be divided into mechanical abuse (squeezing, acupuncture, collision, etc.), electrical abuse (external short circuit, overcharge, over-discharge), thermal abuse (loose contact of high-voltage connectors, electrode-collector contact failure), internal short circuit (diaphragm failure) and other factors cause the single battery to heat up violently. The high temperature and fire caused by a large amount of heat accumulation will cause thermal runaway in surrounding batteries. This causes thermal runaway to spread inside the battery pack.

2.2 Causes of thermal runaway diffusion

The most direct causes for the spread of thermal runaway in battery systems include energy conduction (including thermal energy, electrical energy, mechanical energy, etc.) from the thermally runaway cell to other cells around it, and fire caused by ejected matter.◆ Thermal energy conduction: When the battery undergoes thermal runaway, the lateral heating generated by the front-side contact of the battery is very severe, causing the temperature gradient inside the heated battery to become larger in the thickness direction. Because the temperature of the battery front end reaches the thermal runaway triggering temperature, thermal runaway spreads.

Figure 3 Thermal runaway propagation

◆ Electrical energy conduction: Thermal runaway of a single cell and the large-area shrinkage of the diaphragm cause an internal short circuit. The two can be causally related to each other, and will eventually cause the energy of the thermal runaway cell to drop rapidly. In the battery module parallel unit, other cells will discharge to the thermal runaway battery cell, causing the temperature of the thermally runaway cell to increase even more. At the same time, the cells close to the thermal runaway cells will discharge with greater power than the cells at the far end, causing their temperatures to rise rapidly, thus promoting the spread of thermal runaway.

◆ Mechanical energy conduction: The thermal runaway of a certain battery cell may affect the mechanical structure of the module, or its explosion may cause an instantaneous release of a large amount of energy, which may also cause a certain degree of mechanical damage to the surrounding cells. These Mechanical damage will increase the risk of failure of its surrounding cells, and in severe cases can directly lead to thermal runaway of its surrounding cells.

◆ Ejecta fire: When the battery thermally runs away, it will eject a mixture of high-temperature gases and particles. These gases are flammable and can easily cause fires. These high-temperature ejections and the flames generated by the their combustion will heat the surrounding batteries, thereby accelerating the spread of thermal runaway.

3.Preventive Measures for Thermal Runaway and Thermal Runaway Propagation

3.1 Improve the quality level of single cells

◆ To reduce the degree of side reactions, you can reduce the specific surface area of active materials, add ceramic coatings to improve the thermal stability of the separator;◆ Add temperature-affecting internal resistance materials (such as PTC or NTC materials) to the porous electrode ratio of positive and negative electrodes;

◆ Change the electrolyte Components to improve stability and reliability (such as developing solid electrolytes, adding functional additives, etc.);

◆ Developing new materials with functions such as flame retardancy, cooling, fire extinguishing, and oxygen isolation;

◆ Designing reliable directional and quantitative release strategies for energy and harmful substances, and cooperate with a structure that can withstand certain mechanical stress to avoid the impact of high-temperature ejections and flames on adjacent battery modules.

3.2 Strengthen battery system design

◆ Improve the accuracy of power delivery (such as dynamic, accurate and appropriate charging and discharging solutions and voltage, current, and temperature monitoring solutions);◆ Thermal diffusion protection design, module design should consider heat insulation and fire prevention measures to delay the time for the surrounding battery cells to ignite when a battery cell in the battery module experiences thermal runaway;

◆ According to the thermal diffusion coefficient of the battery core, design a reasonable battery spacing to avoid an increase in the temperature of adjacent battery cores and reduce the risk of thermal runaway caused by heat conduction;

◆ Adding a current limiting functional component to the circuit can quickly and accurately cut off the loop current when some loop current, voltage, and temperature are abnormal, which can effectively avoid electrical energy conduction;

◆ The battery modules are isolated in different areas within the battery system to reduce the speed of thermal runaway transmission and provide longer escape time for the occupants.

3.3 Active fire protection and flame retardant technology

Thermal runaway is one of the most serious cell failure modes, which may directly cause damage to personal safety and property safety. Many scientific research institutions and companies are committed to using technical means to avoid the causes of thermal runaway in batteries, and to control the occurrence and spread of thermal runaway in lithium batteries by developing stable and reliable fire protection systems. The fire protection and flame retardancy of new energy commercial vehicles can be considered from two aspects: 1) Passive fire protection and flame retardancy; 2) Active fire protection and flame retardancy.

Figure 4 high voltage wire harness

Active fire prevention and flame retardant design can be considered from two aspects: first, in the battery system design, add a fire prevention structure to prevent external flames from directly entering the inside of the box; second, in the power battery system design, add a nitrogen protection device inside the battery box.

Figure 5 Guchen nitrogen fire protection device 3rd generation

At this stage, lithium iron phosphate batteries are commonly used in new energy commercial vehicles around the world. Due to their fast burning speed and large number of ejected mass, lithium battery fires will not only produce poisonous gas, but also ordinary dry powder, foam or gas (heptafluoropropane) fire extinguishers cannot completely extinguish the fire. Therefore, special active fire protection and flame retardant devices for power battery boxes have become an urgent problem for the EV industry. Against this background, Guchen Electronic decided to jointly develop a lithium battery fire protection solution with Yutong Bus Corporation, a world leader in intelligent and new energy bus technology. After 3 years, we finally developed a patented, efficient and safe nitrogen protection system, and created a new fire prevention and flame retardant technology - 98% high purity nitrogen + MTV integrated integration technology.

Figure 6 nitrogen fire protection device equipped on electric buses

It is equipped with industry-unique aviation-grade nitrogen separation system to extract high-purity nitrogen from our vehicle's compressed air in real time, with a nitrogen purity of over 98%. Then high-purity nitrogen is introduced into the battery pack in real time. In addition, the battery pack has a built-in multi-level detection system to maintain the battery pack in an anaerobic environment at all times.

High-purity nitrogen can effectively block air, leaving the inside of the battery in an oxygen-free environment, effectively reducing the risk of fire and greatly improving the safety protection level of the battery. The built-in sensor can monitor the nitrogen pressure value in real time 24 hours a day, realizing real-time nitrogen production and real-time nitrogen charging, so that the nitrogen pressure inside the battery box can be maintained at the set value for a long time. When internal faults such as internal short circuit and thermal runaway occur, the oxygen in the battery box is completely cut off to avoid combustion and ensure that the battery does not catch fire or explode.

Moreover, the system also combines the vehicle's MTV integrated integration technology to achieve early fire perception, intelligent judgment, and early intervention to protect the personal safety of electric commercial vehicles and passenger drivers to the greatest extent.

All designs can effectively and timely solve many problems such as fire and ignition of lithium ion batteries, and provide guarantee for the safe operation of all electric vehicles.

Our next major experiment is to see how the nitrogen protection system protects the lithium-ion battery safety when an internal short circuit or thermal runaway occurs inside the EV battery.

Message

If you are interested in our products, please fill in the message form below. Our sales representative will contact you within 24 hours.