How to Optimize the Cost of High-Voltage Wiring Harnesses in Battery Electric Vehicles

With competition intensifying in today’s NEV market—driven by Tesla’s price reductions and BYD’s public request for suppliers to lower prices—it is clear that the industry will continue entering an even more heated stage. To survive and grow, OEMs must rely not only on high-quality, high-value products but also on leading technologies. While technological innovation continues, automakers are paying increased attention to component cost optimization as a way to strengthen product competitiveness.

Among these components, the HV wiring harness—one of the highest-value parts in a BEV—naturally becomes a key target for cost reduction.

Typical HV harness types include:

◆Battery high-voltage harness

◆Motor controller harness

◆DC fast-charging harness

◆AC slow-charging harness

◆Air-conditioning HV harness

◆General charging HV harness (between the PDU, OBC, compressor, and battery heater)

A complete HV harness is composed of HV connectors, HV cables, protective coverings (tapes, heat-shrink tubing, corrugated tubes, self-wrapping sleeves), brackets, etc.

The manufacturing process typically includes:

Cutting → Sub-assembly → Terminal crimping/ultrasonic welding → Shield crimping → Overall assembly → Electrical testing.

◆Material cost

◆Manufacturing/labor cost

◆Packaging and logistics

◆Overhead & management costs

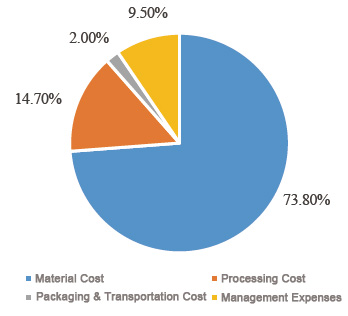

Material cost accounts for the largest proportion—approximately 73.8% according to a typical vehicle’s cost breakdown. Therefore, reducing material cost and optimizing design/manufacturing processes are essential for overall cost reduction.

◆Scale-based reduction

◆Supplier collaboration

◆Technology-based reduction

Among them, technology-based cost reduction is the most effective and sustainable. It uses methods such as:

Removing redundant features

Increasing localization

Standardization and platform-level unification

This study focuses on technology-based methods for HV harness cost optimization.

A well-optimized architecture can significantly reduce the number of connectors and unnecessary HV wiring.

In the original system architecture:

The PDU performed only power distribution functions, creating extra transfer points.

HVH and PTC had similar heating functionalities.

Charging inlets were located far from mating components, increasing cable length.

PDU and IPU were integrated, eliminating one PDU assembly and one motor-controller harness (saving ~1.5 m of 50 mm² cable and two pairs of Ø8 mm connectors).

HVH and PTC functions were combined, removing one HV loop (saving ~1.5 m of 3 mm² cable and two pairs of terminals).

Total savings: approx. RMB 730 by eliminating 4 HV connectors and two HV harnesses.

Example: Charging inlet relocation

AC and DC charging inlets were placed on the left/right rear quarter panels.

Slow-charging harness length: ~4.5 m

Fast-charging harness length: ~4.0 m

Inlets were moved to the left/right fenders, closer to the OBC and battery pack, significantly shortening cable length.

Cost reduction: approx. RMB 260

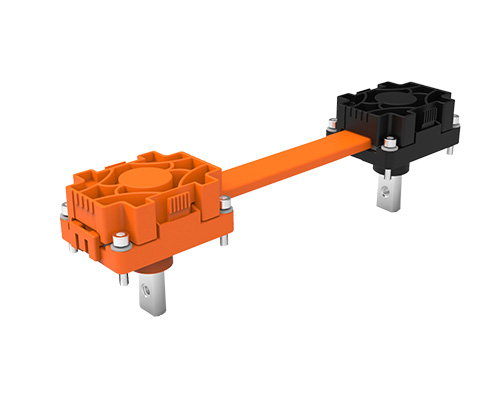

(1)Integrated charging inlet design

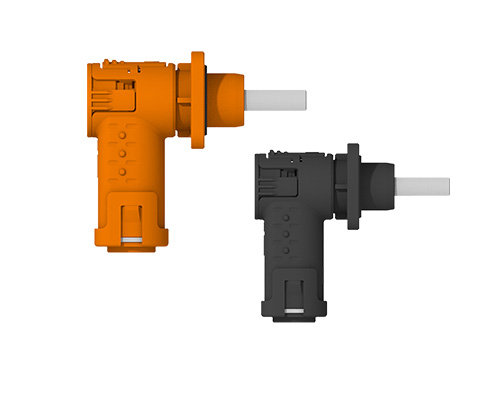

(2) Localization of HV connectors

Replacing imported TE or other global-brand connectors with domestic brands (e.g., Luxshare, Ebusbar, Guchen) delivers significant savings with comparable performance.

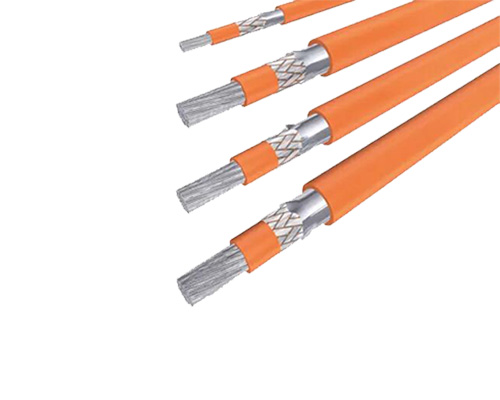

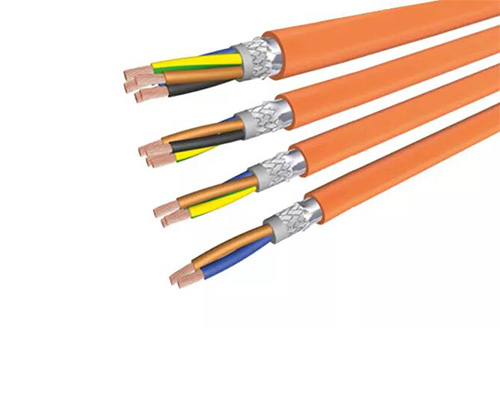

(3) Cable cross-section optimization

By interpreting regulations, benchmarking, and analyzing cloud-based big data, the cross-section of high-voltage cables can be optimized. For specific high-voltage cables, customization can be achieved by optimizing parameters such as conductor cross-section, temperature rating, flexibility, and shielding performance, thereby avoiding oversizing and excessive components. Taking fast-charging high-voltage cables as an example, the cable cross-section was reduced from 70 mm² to 50 mm² after optimization, while still fully meeting actual charging requirements.

(4) One-to-many material optionality

Develop multiple qualified options for each major material (e.g., cables, connectors), allowing Tier-1 suppliers to leverage supply chain advantages and select optimal-cost solutions. Taking high-voltage cables, which account for a relatively large proportion of material costs, as an example: currently, the main specifications of high-voltage shielded cables are developed according to a “one-to-many” approach based on high-voltage cable standards. For each cable specification, multiple variants are available from the harness supplier. The specific conductor configuration for each circuit needs to be confirmed based on the actual vehicle load conditions. Through continuous design optimization, many materials can now be offered with multiple options under a one-to-many selection scheme.

Cost reduction is a long-term and iterative process. Ongoing improvements in system architecture design, routing, materials, and platform strategies will help OEMs significantly reduce total vehicle cost and deliver more competitive BEV products to the market.

Among these components, the HV wiring harness—one of the highest-value parts in a BEV—naturally becomes a key target for cost reduction.

1. Overview of High-Voltage Wiring Harnesses

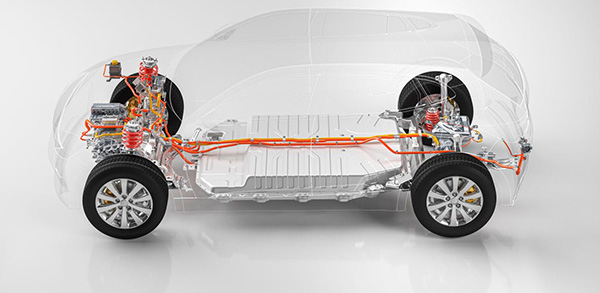

HV wiring harnesses interconnect components within a vehicle’s high-voltage system, serving as the medium for power transmission. They carry high-voltage and high-current loads while ensuring electromagnetic shielding and safety performance. HV wiring harnesses act as the “nervous system” of an electric vehicle and are critical to vehicle performance and safety.Typical HV harness types include:

◆Battery high-voltage harness

◆Motor controller harness

◆DC fast-charging harness

◆AC slow-charging harness

◆Air-conditioning HV harness

◆General charging HV harness (between the PDU, OBC, compressor, and battery heater)

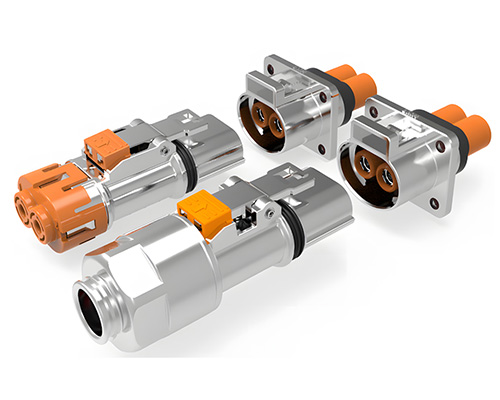

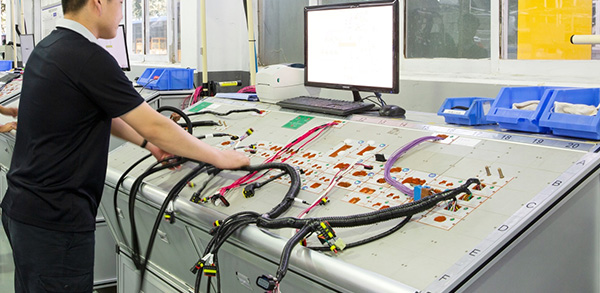

A complete HV harness is composed of HV connectors, HV cables, protective coverings (tapes, heat-shrink tubing, corrugated tubes, self-wrapping sleeves), brackets, etc.

The manufacturing process typically includes:

Cutting → Sub-assembly → Terminal crimping/ultrasonic welding → Shield crimping → Overall assembly → Electrical testing.

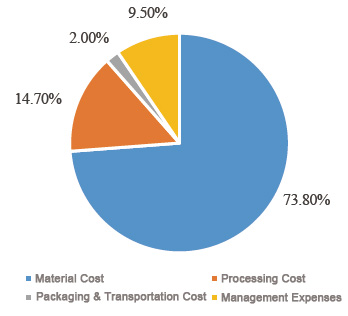

2. Cost Structure of High-Voltage Wiring Harnesses

The total cost of an HV wiring harness consists of:◆Material cost

◆Manufacturing/labor cost

◆Packaging and logistics

◆Overhead & management costs

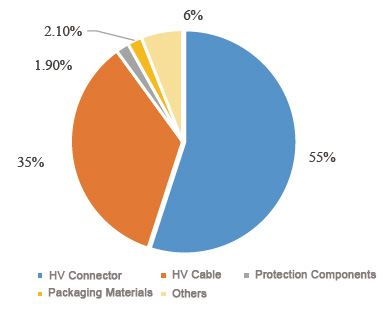

Figure 1. HV Wiring Harness Cost Breakdown

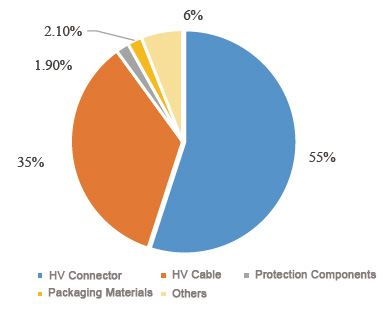

Figure 2. Material Cost Structure of High-Voltage Harnesses

Material cost accounts for the largest proportion—approximately 73.8% according to a typical vehicle’s cost breakdown. Therefore, reducing material cost and optimizing design/manufacturing processes are essential for overall cost reduction.

3. High-Voltage Wiring Harness Cost-Reduction Study

Automotive cost reduction typically involves three approaches:◆Scale-based reduction

◆Supplier collaboration

◆Technology-based reduction

Among them, technology-based cost reduction is the most effective and sustainable. It uses methods such as:

Removing redundant features

Increasing localization

Standardization and platform-level unification

This study focuses on technology-based methods for HV harness cost optimization.

3.1 High-Voltage System Architecture Optimization

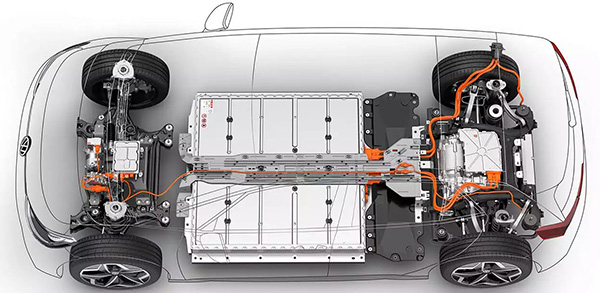

A BEV’s HV system consists of components such as the battery pack, 3-in-1 powertrain (inverter + motor + reducer), PDU, electric compressor (ECP), 2-in-1 (OBC + DC-DC), battery heater (HVH), cabin heater (PTC), AC slow-charging inlet, DC fast-charging inlet, and HV harnesses.A well-optimized architecture can significantly reduce the number of connectors and unnecessary HV wiring.

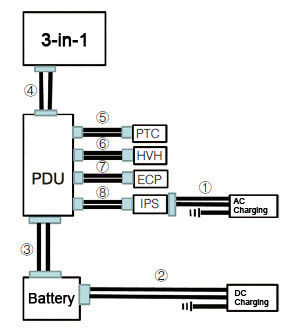

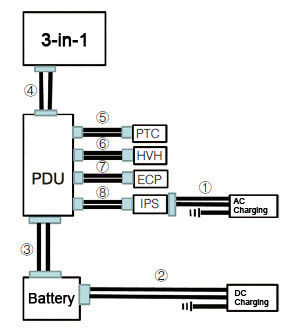

Figure 3. High-Voltage System Architecture (Before Optimization)

Example of OptimizationIn the original system architecture:

The PDU performed only power distribution functions, creating extra transfer points.

HVH and PTC had similar heating functionalities.

Charging inlets were located far from mating components, increasing cable length.

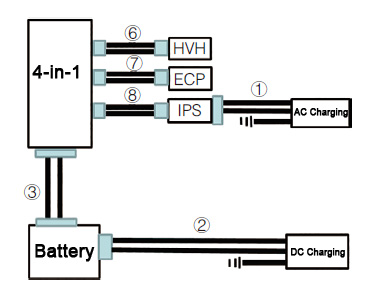

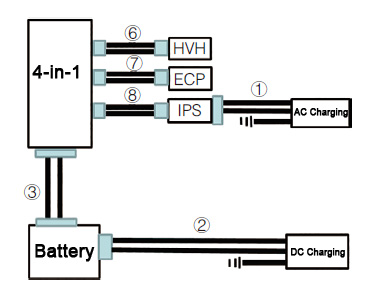

Figure 4. High-Voltage System Architecture (After Optimization)

Through optimization:PDU and IPU were integrated, eliminating one PDU assembly and one motor-controller harness (saving ~1.5 m of 50 mm² cable and two pairs of Ø8 mm connectors).

HVH and PTC functions were combined, removing one HV loop (saving ~1.5 m of 3 mm² cable and two pairs of terminals).

Total savings: approx. RMB 730 by eliminating 4 HV connectors and two HV harnesses.

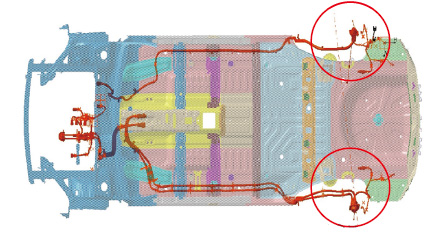

3.2 High-Voltage Harness Routing Optimization

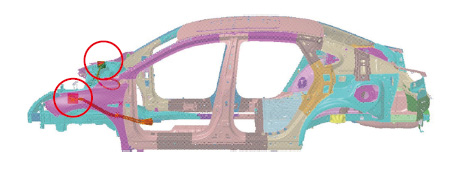

Optimizing cable routing for each model can reduce cable length and material usage.Example: Charging inlet relocation

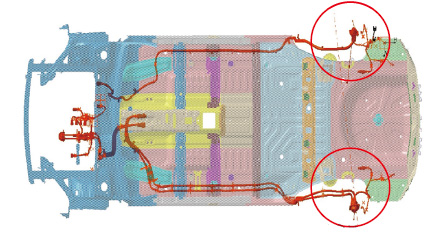

Figure 5. Pre-Optimization Fast and Slow Charging Port Layout Diagram

Before optimization:AC and DC charging inlets were placed on the left/right rear quarter panels.

Slow-charging harness length: ~4.5 m

Fast-charging harness length: ~4.0 m

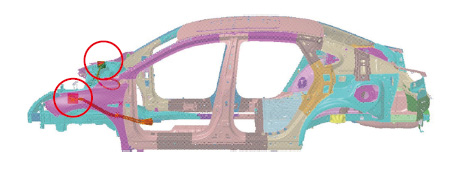

Figure 6. Post-Optimization Fast and Slow Charging Port Layout Diagram

After optimization:Inlets were moved to the left/right fenders, closer to the OBC and battery pack, significantly shortening cable length.

Cost reduction: approx. RMB 260

3.3 Material Optimization for High-Voltage Harnesses

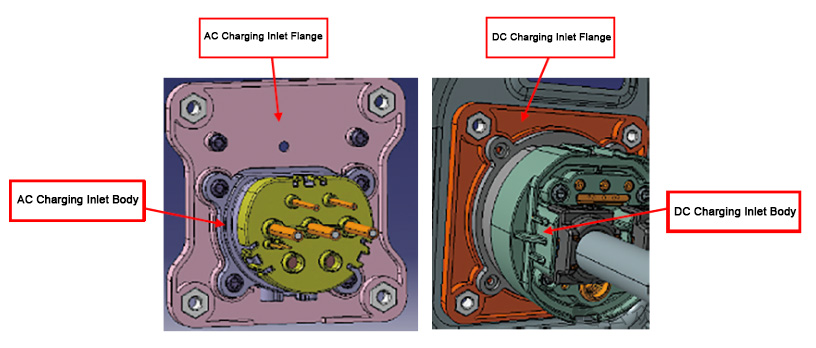

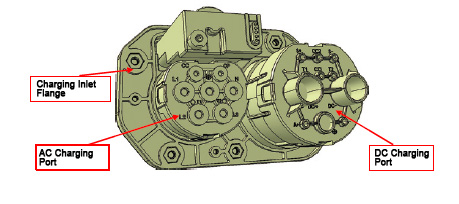

As material cost dominates total HV harness cost, the following strategies are emphasized:(1)Integrated charging inlet design

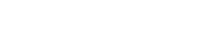

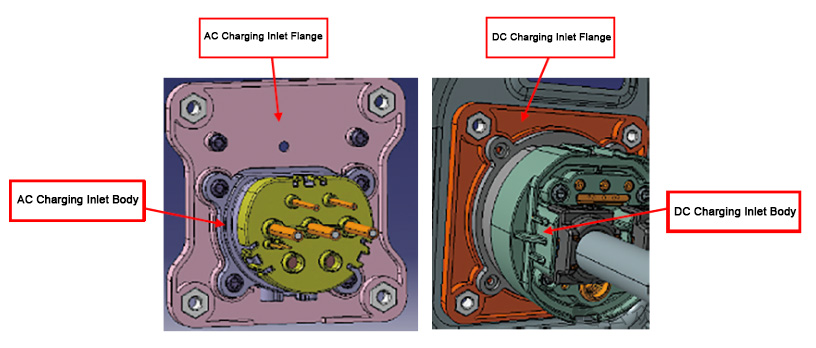

Figure 7. Pre-Optimization Split-Type Charging Inlet

Originally, AC and DC inlets were separate modules, with higher cost.

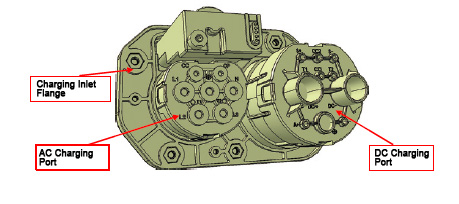

Figure 8. Post-Optimization Integrated Charging Inlet

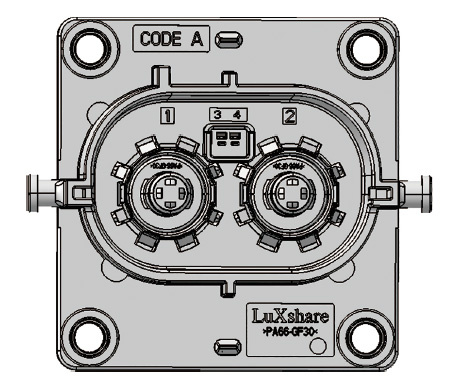

Unified platform design enables an integrated inlet module, reducing tooling and component cost (saving ~RMB 8 per set).(2) Localization of HV connectors

Replacing imported TE or other global-brand connectors with domestic brands (e.g., Luxshare, Ebusbar, Guchen) delivers significant savings with comparable performance.

| Original Brand | Original Model | Chinese Brand | Chinese Model |

| TE | 1-2374299-1 | Ebusbar | 123-0500-0002 |

| TE | 2-2356258-2 | Luxshare | HVP800022CVA11 |

| Amphenol | PL28X-301-70 | Guchen Electronics | GCMC1-28X-301-70 |

| Amphenol | PL183U-40-2.5 | Guchen Electronics | PRC183U-40-2.5 |

Table 1. Localization Case Study of High-Voltage Connectors

(3) Cable cross-section optimization

By interpreting regulations, benchmarking, and analyzing cloud-based big data, the cross-section of high-voltage cables can be optimized. For specific high-voltage cables, customization can be achieved by optimizing parameters such as conductor cross-section, temperature rating, flexibility, and shielding performance, thereby avoiding oversizing and excessive components. Taking fast-charging high-voltage cables as an example, the cable cross-section was reduced from 70 mm² to 50 mm² after optimization, while still fully meeting actual charging requirements.

(4) One-to-many material optionality

Develop multiple qualified options for each major material (e.g., cables, connectors), allowing Tier-1 suppliers to leverage supply chain advantages and select optimal-cost solutions. Taking high-voltage cables, which account for a relatively large proportion of material costs, as an example: currently, the main specifications of high-voltage shielded cables are developed according to a “one-to-many” approach based on high-voltage cable standards. For each cable specification, multiple variants are available from the harness supplier. The specific conductor configuration for each circuit needs to be confirmed based on the actual vehicle load conditions. Through continuous design optimization, many materials can now be offered with multiple options under a one-to-many selection scheme.

| Harness Material | Brand | Model |

| 50mm2 Silicone Rubber HV Shielded Cable | Coroplast | FHLR2GCB2G-50 |

| Huacheng | FHLR2GCB2G-50 | |

| LEONI | FHLR2GCB2G-50 | |

| Beijing Force | FHLR2GCB2G-50 |

Table 2. Example of One-to-Many Material Selection

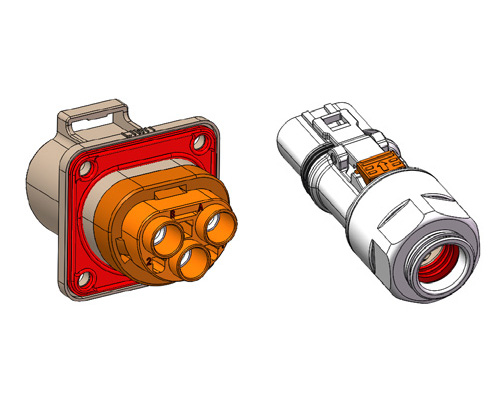

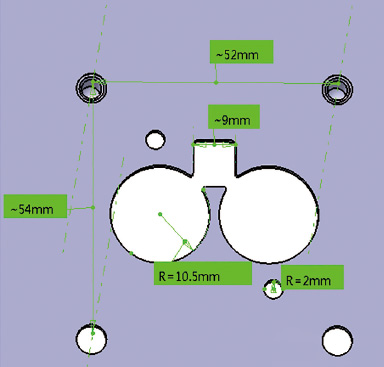

3.4 Platform and Standardization Design

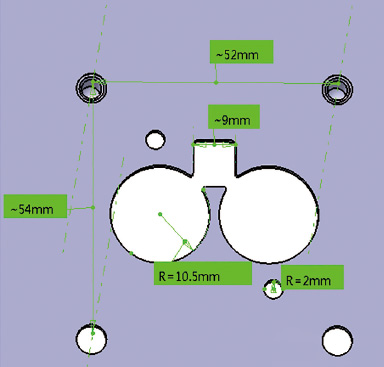

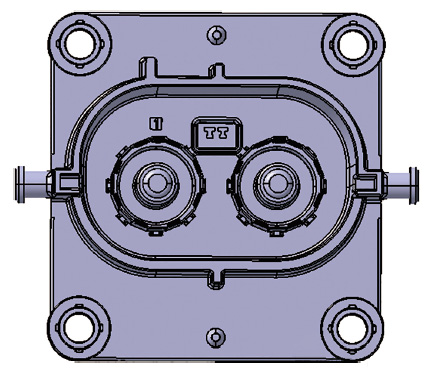

By implementing platformization and standardization in both vehicle harness principles and raw materials, the development cycle of the full vehicle harness can be significantly shortened, repetitive validation tests can be reduced, and harness costs can be lowered. Continuous platformization and standardization of harness materials reduce the variety of materials while increasing the quantity of each individual material, achieving economies of scale and contributing substantially to cost reduction. Through research and analysis, platformization and standardization of secondary materials (such as connectors, cables, and auxiliary materials) can significantly reduce high-voltage harness material costs. The following illustrates an example of high-voltage connector platformization: under the same electrical performance requirements, the openings on the aluminum panel of the battery pack can accommodate board-end connectors from different brands (TE, Luxshare), as shown in Figures 9, 10, and 11. This platformized design demonstrates strong versatility.

Figure 9. Hole dimensions on the aluminum panel of the battery pack

Figure 10. TE HVP2P800

Figure 11. Luxshare HVP2P800

4. Conclusion and Outlook

Due to high voltage, high current, and large conductor cross-sections, HV wiring harnesses face challenges such as routing complexity, safety requirements, shielding, weight, and cost. As one of the most valuable components in BEVs, continuous optimization of HV harnesses contributes directly to vehicle-level cost competitiveness.Cost reduction is a long-term and iterative process. Ongoing improvements in system architecture design, routing, materials, and platform strategies will help OEMs significantly reduce total vehicle cost and deliver more competitive BEV products to the market.

Message

If you are interested in our products, please fill in the message form below. Our sales representative will contact you within 24 hours.