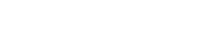

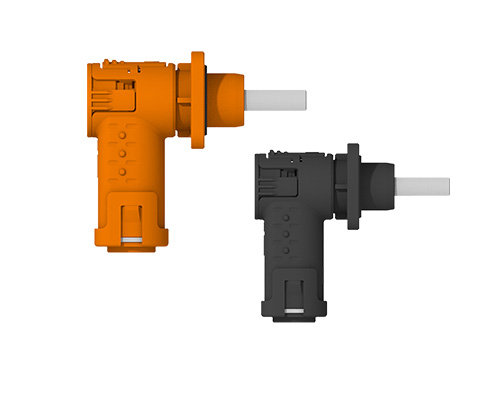

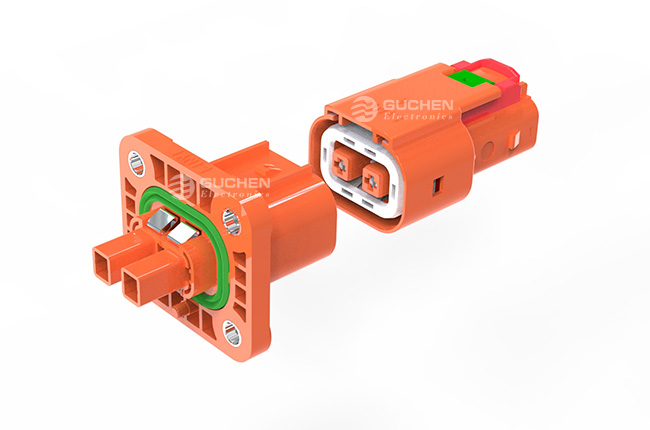

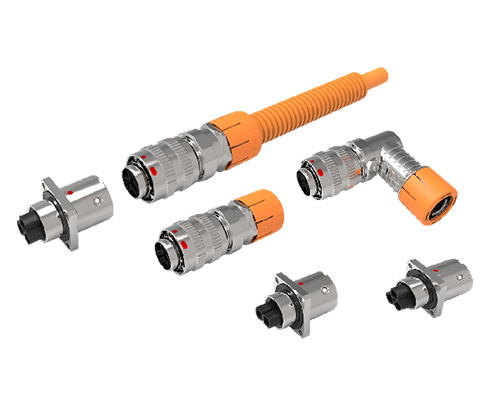

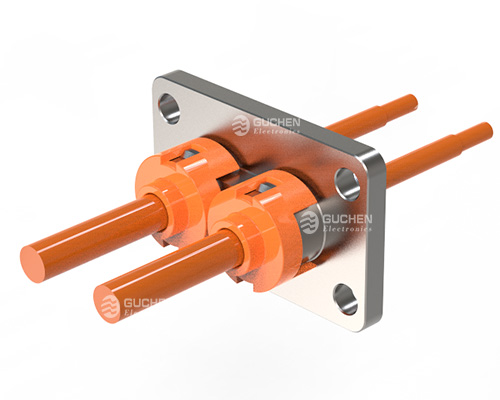

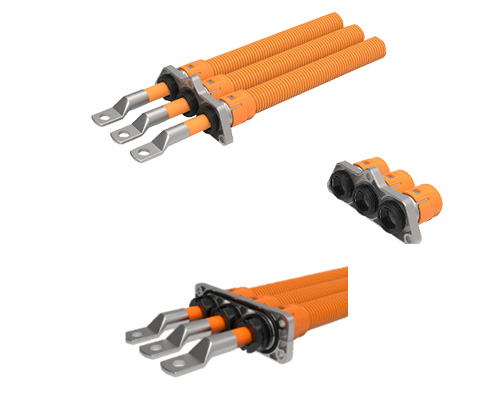

GVA Series 30A 2-Pin High Voltage Plastic Connector

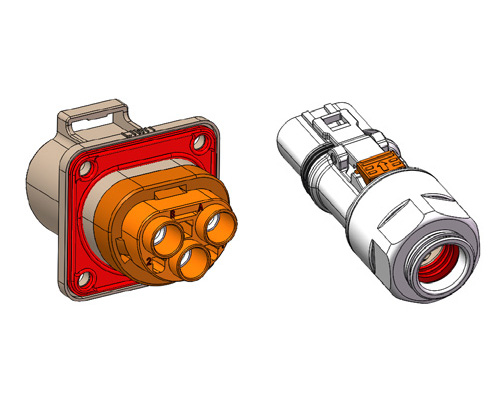

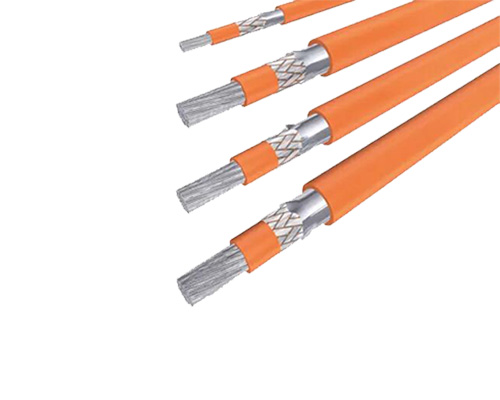

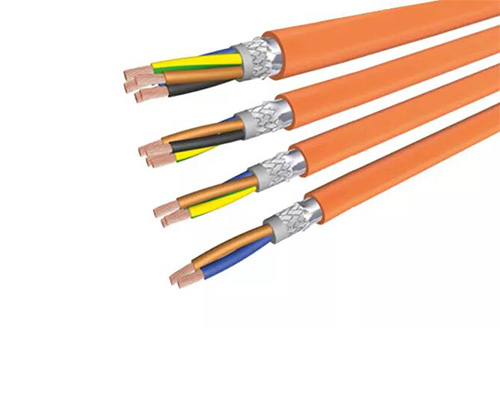

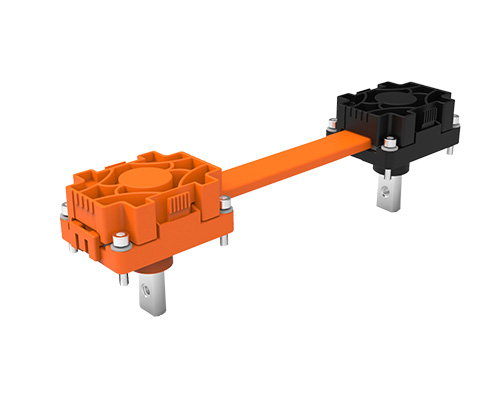

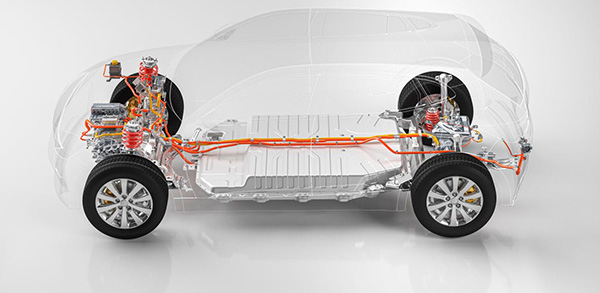

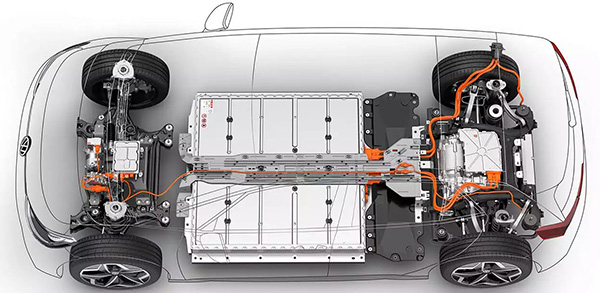

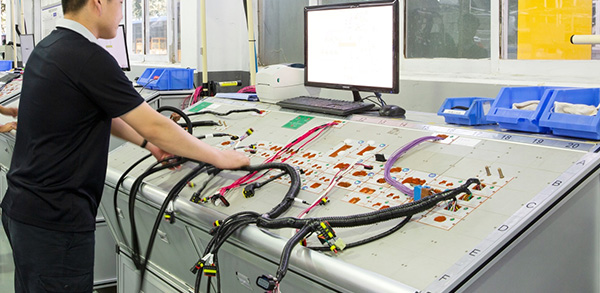

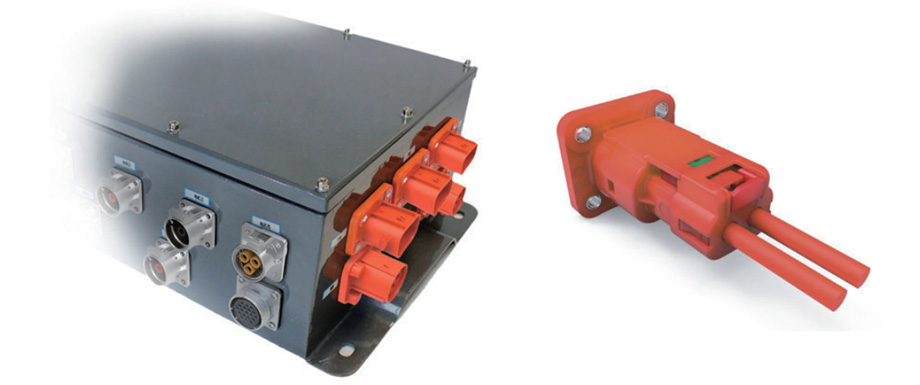

The GVA Series High Voltage Connector is a compact, lightweight, and high-reliability solution designed for auxiliary high-voltage systems in electric passenger vehicles and commercial vehicles. It is optimized for small three-electric applications, including DC-DC converters, On-Board Chargers, PTC heaters, electric compressors, HVAC systems, and other low-power HV modules.

With a rated voltage of up to 1000V DC, 360° electromagnetic shielding, and IP68/IP6K9K sealing, the GVA Series delivers safe, stable, and long-term performance in demanding automotive and electrification environments.

With a rated voltage of up to 1000V DC, 360° electromagnetic shielding, and IP68/IP6K9K sealing, the GVA Series delivers safe, stable, and long-term performance in demanding automotive and electrification environments.

Temp Range :

-40°C~+140°C

-40°C~+140°C

Max current:

30A

30A

Rated Voltage :

1000V DC

1000V DC

Sealing Class :

IP68 & IP6K9K

IP68 & IP6K9K